Abstracts

Abstract

Although the natural availability and quality of wood is variable across the Arctic, there is great continuity in how it was traditionally used. This article considers the value of wood to Arctic peoples and the criteria that would distinguish the utility of different pieces. The topic is explored in the case of kayak construction, one of the most complex carpentry tasks that can be inferred from many archaeological sites. Numerous types of kayaks were built in several periods by a variety of peoples using very different toolkits. Using both ethnographic and archaeological examples, it is shown that this technology everywhere shared several key stages of construction. Within these stages, specific carpentry tasks defined the criteria that all kayak builders used to select wood. By exploring the value of wood to Arctic peoples for carpentry, this article demonstrates the potential for understanding wood use through experimental archaeology.

Résumé

Bien que la disponibilité naturelle et la qualité du bois soient variables à travers l’Arctique, son usage traditionnel manifeste une grande continuité. Cet article examine la valeur du bois pour les peuples de l’Arctique et les critères de sélection des différents bois en fonction de leur utilité. Ce sujet est abordé par le biais de la construction des kayaks, l’une des tâches de menuiserie les plus complexes que l’on peut inférer d’après plusieurs sites archéologiques. De nombreux types de kayaks ont été construits durant plusieurs périodes par divers peuples utilisant des trousses d’outils différentes. Au moyen d’exemples tant ethnographiques qu’archéologiques, nous montrons que les étapes essentielles de la construction étaient largement partagées. Au sein de ces étapes, certaines tâches de menuiserie spécifiques définissaient les critères qu’utilisaient tous les constructeurs de kayaks pour sélectionner leurs bois. En examinant la valeur du bois de menuiserie pour les peuples de l’Arctique, cet article démontre le potentiel de l’archéologie expérimentale pour la compréhension de l’usage du bois.

Article body

Introduction

Although wood was an important but often scarce resource among the circumpolar Inuit, as shown by both ethnohistory and archaeology, much less is known about the criteria that determined the value of one piece over another (Alix and Brewster 2004). Arctic ethnography is replete with accounts of individuals going to extraordinary lengths to procure the right piece of wood, often making incredible journeys to trade or spending days sorting through driftwood. Wood is a diverse material; various pieces have very different properties and their utility is often relative to specific carpentry tasks. Understanding the wood-selection criteria can tell us much about how Arctic peoples interacted with and perceived their environment (Alix 2009; Wheeler and Alix 2004).

Several factors determined the structural utility of wood for kayak construction, one of the most complex carpentry tasks that can be inferred from many Arctic sites (e.g., Grønnow 1994; Gulløv 1997). Kayaks have a long history in the Arctic, having been built and used in roughly similar ways by a variety of cultures, including at least some Palaeoeskimo, Ipiutak, Aleut, Yup’ik, and most ancestral/descendant Inuit groups (Arima 1987; Brand 1991; Larsen 2001; Meldgaard 2004). This article will describe a general operational sequence and four structural components that all known types of kayak frame shared. These core components will be defined sequentially, with reference to ethnohistorical accounts and to kayaks preserved in ethnographic collections and archaeological assemblages. When making these components, all kayak builders from a variety of technical traditions shared certain wood-selection criteria.

Carpentry in the Arctic

Today, wood is easily shaped by power tools and often imagined to be a homogenous malleable material with few limits to whatever forms can be produced. These possibilities were much more restricted, however, for users of diverse toolkits ranging from the knapped tools of the Arctic Small Tool tradition to the meteoritic and traded iron of the Late Dorset and Thule peoples, and even to later Inuit modifications of European tools. An intimate knowledge of wood’s natural structure was required to carve it into useful pieces (Alix 2007, Arima 1975; Grønnow 1996; Walls 2010; Zimmerly 1979).

Wood is a diverse material because its forms and characteristics depend on how trees grow and decay. Different tree species have different anatomies and types of wood with distinct internal structures that determine buoyancy, flammability, grain direction, hardness, strength, weight, and other properties (Hoadley 2000). Within each species, these characteristics also reflect the unique life history of each tree—events such as competition for sunlight, disease, drought, fire, and insect damage. These characteristics vary even within a single tree. Inside twists and branches, the grain is heavier and more compressed with a natural curvature; within the trunk, it is generally straighter. Heartwood is heavier, denser, and nearer the pith, whereas sapwood is lighter, more pliable, and closer to the bark. Indeed, even the history of decomposition makes each piece of wood different; greenwood, i.e., wood recently removed from a tree, differs greatly from driftwood or dry seasoned wood. No two pieces of wood are exactly alike, and carpenters have to choose their material carefully.

Across the Arctic, wood is often extremely scarce, and for many places the only natural source is driftwood (Dyke et al. 1997; Tremblay et al. 1997). By the time driftwood is deposited on Arctic shores, it is usually in poor condition, having been waterlogged, battered by ice, and partially decomposed. While exotic types can occasionally be found, Arctic driftwood is predominantly from softwood species that grow along rivers in the boreal forests of North America and Siberia, including spruce (Picea), pine (Pinus), fir (Avies), and cedar (Cedrus) (Grønnow 1996). Wood was one of the most popular items brought by Europeans during the colonial period; in many parts of the Arctic, wood had a high trading value and was often scavenged from shipwrecks and abandoned posts.

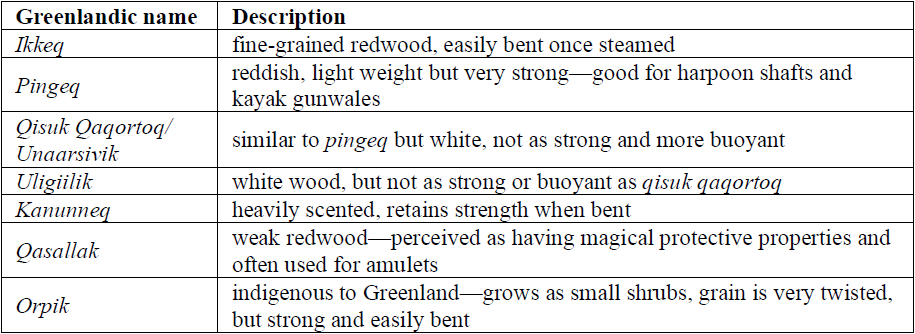

Inuit generally distinguished a multitude of wood types, which were not necessarily synonymous with the tree species from which they originated. These types were generally differentiated by properties such as weight, straightness of grain, colour, utility for specific carpentry tasks, and even supernatural qualities. For example, West Greenlanders distinguished at least seven types of wood that came primarily from spruce, pine, fir, and cedar (Table 1) (Petersen 1986: 18-19). Wood types were classified by utility in most Inuit, Yup’ik, and Aleut groups (Alix 2007; Wheeler and Alix 2004; Zimmerly 1979).

Table 1

Greenlandic naming of wood types with descriptions (after Petersen 1986: 18-19)

Variability of structural components

Although kayaks preserve poorly in archaeological contexts, inferential evidence points to their importance for hunting and transportation in many Arctic cultures. The oldest conclusive evidence for their use consists of ribs and paddles from the Saqqaq site of Qeqertasussuk, indicating that kayaking was practised as far back as 3,900 years ago (see Grønnow 1994, 1996, this issue; Meldgaard 2004). Kayaks played an important role in the migration of the Thule people, whose art—such as carvings on bow-drill handles—clearly shows that kayaks were used alongside umiaqs to hunt bowhead whales (Arima 1975: 89; Whitridge 1999: 191, 355). Kayaks continued to serve a variety of purposes among Thule-descended groups from Siberia to Greenland, with only a few notable exceptions (e.g., Gilberg 1974). Despite their great variety of stylistic types and their diverse purposes, all kayaks share the same structural components and posed similar carpentry challenges for kayak builders across the Arctic.

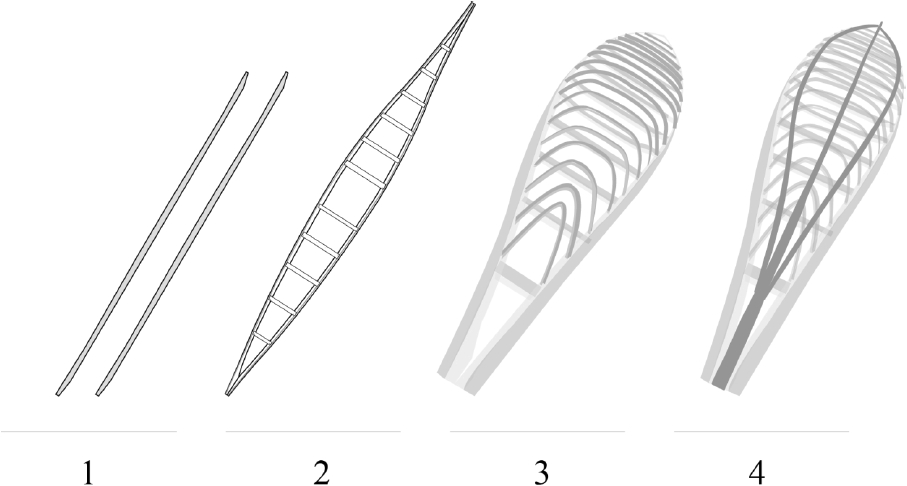

Figure 1

Four general stages of construction shared by kayaks from across the Arctic: 1) gunwales; 2) crosspieces; 3); ribs; 4) stringers and keel

While kayak types vary a great deal across the Arctic, four structural components define most of them: gunwales, crosspieces, ribs, and stringers (Figures 1 and 2). Indeed, these components are described by approximately the same terminology across the many dialects and language families of kayak users. As depicted in Table 2, the similarity is especially strong among Inuktitut dialects, but overlapping cognates are present even in the more distantly related Aleut and Yup’ik languages. Bergsland (1991: 158) presents this as evidence that kayaks may have been used and built before the Eskimo-Aleut language family began to split up. The evidence from Qeqertasussuk, while fragmentary, suggests that Saqqaq kayaks also shared these structural components (Grønnow 1994; Walls 2010). For skin kayaks of any type, these four components essentially function as a “tent-like” structure, being positioned to hold the skin covering in the desired hull shape with a minimum of contact points.

Table 2

Comparison of names for the four structural components of a kayak. The phonology is not standardised and terms are left in their source format

General kayak construction sequence

This section will present the construction stages that are common to all kayaks. Additional features may vary considerably from one kayak to another, thereby producing many different functional and stylistic types. However, the following are the key stages of kayak construction as a whole and represent the critical carpentry skills. A West Greenlandic example, housed at the Sisimiut Museum, is used for illustration, but the text itself draws on documents by a number of authors and refers to construction of different kayak types from all over the Arctic (Arima 1975, 1987; Brand 1991; Golden 2006; Petersen 1986; Zimmerly 1979). Because of dialectical variability, English terminology will be used where possible.

Figure 2

General aspects of kayak frames

Gunwales

Kayak assembly necessarily starts with the two gunwales, which are the primary structural components around which everything else is built. Gunwales determine the symmetry of the hull; they constitute the bulk of its length and also determine the sheer (profiled curvature of the deck). The gunwales essentially hold the kayak together through tension. They are bound at each end and then are forced apart in the middle, thus creating pressure that holds the frame together in the middle (Figures 2 and 3). Kayaks are subject to many different stresses during normal operation: the weight of the hunters themselves; sudden movements during stalking and striking of animals; and the impact of waves as the craft moves through the water. Gunwales must be the strongest part of the kayak, and the natural grain of the wood must stretch longitudinally from tip to tip. Weak points exist where the grain intersects the sides of the gunwale, and these places will snap first when enough pressure is applied (Figure 3). A gunwale damaged in this way could have catastrophic consequences, as the frame would simply collapse under the kayaker’s weight and the external water pressure.

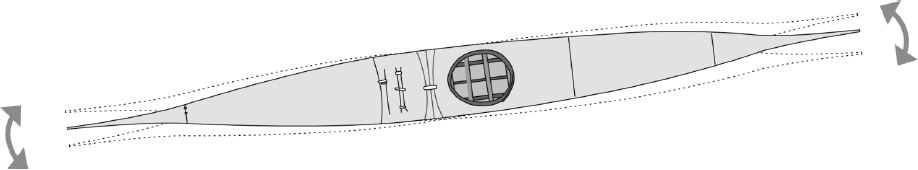

Figure 3

Tensile pressures in gunwales and importance of grain selection

The most critical stage of kayak construction, at least in terms of wood selection, is ensuring that both gunwales are exactly the same strength and will bend equally. If one gunwale strake is stronger than the other, it will impact the symmetry of the kayak and cause the shape to be straighter on one side than on the other. Asymmetry affects navigation, as the hull will not follow a straight path through the water (Figure 4); the kayaker will constantly have to correct the course, thus interfering with the functionality of the kayak in a number of ways. This is a serious shortcoming, since Inuit hunters at times travelled hundreds of kilometres over water. Additionally, a symmetrical hull is a necessity for most forms of hunting, from seal harpooning to caribou lancing, because the hunter has to make as little noise as possible. In general, the hunter has to line the kayak up in the right direction and silently paddle a few strokes to within striking range. Such a silent approach would be compromised by any course corrections due to an asymmetrical hull (e.g., Nansen 1893).

Figure 4

The importance of equalising both gunwales

Equalising the gunwales to make them symmetrical requires not only special carpentry skills, but also the right material. One must choose long pieces of wood that have as straight a grain as possible—any natural twisting, common to most pieces of wood, will affect the way that the gunwales bend when drawn apart. The ideal material for a gunwale is a single piece, long and straight enough, with as few knots as possible; ideally, both gunwales should be made by splitting a single piece into two pieces that are equally strong because they share the same internal structure (Arima 1975: 110-111; Petersen 1986: 22).

In many parts of the Arctic, it is extremely rare to find driftwood of the quality and length to make gunwales out of a single piece (Alix 2009; Grønnow 1996). Many kayaks collected from around the Arctic have gunwales that are assembled from multiple pieces, which are scarfed together by a variety of different joints. Figure 5 shows several examples of scarfed gunwales, including three from different archaeological contexts in Greenland. In all cases, each gunwale segment has very straight grain, even though the pieces are not long enough to span the entire length of the kayak. Scarf joints were probably the primary way of building gunwales before wood became available commercially. Wherever ideal pieces of driftwood were unavailable, or wherever scarfing was preferred to achieve a specific form, builders evaluated different pieces in terms of their compatibility with each other and how they could be assembled and bound together.

Figure 5

Examples of composite gunwale strakes: a) a Netsilik kayak collected by the 5th Thule Expedition (photo: courtesy of the Danish National Museum, item P30 161); b) from the Illorpaat site in West Greenland (see Gulløv 1997: 147) (photo: courtesy of the Greenland National Museum, item IGD 3696); c) from an archaeological site at Nordbø, South Greenland by H.C. Petersen (photo: courtesy of the Greenland National Museum, item KNK 171); d) a piece of the Morris Bay kayak, from Washington Land, North Greenland (see Mathiassen 1928) (photo: courtesy of the Greenland National Museum, item KNK 122). All photos by Matthew Walls

Crosspieces

Once the two gunwales have been matched to form a symmetrical outline, they are held in the desired shape by crosspieces (Figures 2 and 6). Crosspieces have to be securely attached to the gunwales so that they can hold the gunwales in the correct position and will not loosen during normal operation. Crosspieces also have to be shaped and fitted well enough to prevent creaking that would compromise stalking of prey as the kayak moves. For this, a number of different techniques can be used. Mortises can be made in the gunwales, and carved crosspieces placed into them in a locking position. Other strategies employ a more flexible joint where the crosspiece is mortised only halfway and is lashed into place using a variety of materials such as bearded sealskin line and braided sinew. The archaeological examples in Figure 5 show mortises cut only partially into the gunwale, whereas in many examples the joints are fully locked (Petersen 1986). In either case, when carving into the gunwales, the builder has to carve perpendicular to the grain to form a mortise so that the crosspiece can be tightly placed. Again, gunwales need to have a straight grain, as mortises further weaken the frame, and such weakening is especially problematic where the grain “runs out” of the strake (Figure 3).

Figure 6

Interior of a Greenlandic kayak: a) cambered crosspiece mortised securely to the gunwale; b) cambered crosspiece mortised securely to the gunwale; c) ribs mortised to the gunwale; d) stringer held in position by the ribs. Photo: courtesy of the Danish National Museum, item Lc. 148, photographer: Matthew Walls

Many different kayak types include crosspieces that are cambered to raise the deck above the gunwales. In most Bering Strait and Aleutian types, the entire length of the deck is raised, and all of the crosspieces arched. For most Eastern Arctic types, the deck is only elevated immediately forward of the cockpit, to provide enough room for the kayaker’s legs. In Eastern Arctic kayaks, the first crosspiece in front of the cockpit is usually called the masik, the same word for the gill of a fish (Arima 1975: 108). The masik must be curved, and strong enough to take the weight of a hunter’s body entering the kayak (Figure 2). Curved deck pieces must follow the desired arc shape, while being robust enough to withstand a variety of forces. Such deck pieces tend to be made from naturally curved wood. In the first two crosspieces visible in Figure 6 (a and b), the grain follows the curvature to both ends of the piece. Zimmerly’s (1979: 4-6) ethnographic depiction of Hooper Bay kayak construction also shows the builder (Dick Bunyan) making crosspieces out of wood from a tree stump, where the grain runs from the trunk to the root at a point where it matches the desired shape (see also Andrew 2008: 244-298).

Ribs

The gunwales and the crosspieces together form the top deck and determine the dimensions of the hull from a top-down perspective, but not its cross section. The ribs span the distance between the gunwales, thus determining its depth and shape at any particular cross section (Figures 2 and 6). Together with the placement of the stringers, the ribs determine the volume of the hull, as well as many performance characteristics, such as manoeuvrability and stability. Different hull types vary considerably in their number of ribs, but all of these designs share the basic requirement of collectively supporting the kayaker’s weight, and the pressures the ribs exert during operation (e.g., during rolling). Because of the shape of the gunwales, no two ribs in a kayak are exactly the same shape or size, and each rib must be individually tailored to create the desired hull.

Unlike the cambered crosspieces, the arc of the ribs is usually too extreme for one to find pieces of driftwood that naturally have the desired grain curvature. A number of techniques can be used to bend the ribs permanently into the required shape, mostly by some variation of soaking, heating, steaming, and clamping the inside curve of preformed pieces—often using the builder’s teeth (Petersen 1986; Zimmerly 1979). In order for the wood to bend without snapping, the grain needs to be perfectly straight without intersecting the sides. Even if a rib with an angled grain does not break while being bent into shape, it will remain a weak point of the frame and be prone to snapping during operation (Figure 7). While broken ribs are not as critical a problem as broken gunwales, they can stick out into the skin, causing asymmetry in the hull shape. The ribs are generally mortised securely into the gunwales as depicted in Figure 5. As with wood selection for the gunwales, a straight grain is necessary, but the small size makes it possible to use several alternatives to driftwood. For example, in Greenland, it was very common to use locally available dwarf birch (Betula nana) and willow (Salix arctica)—referred to as orpik in Table 1 (Petersen 1986).

Figure 7

Bending ribs

Stringers

Once the ribs are securely mortised or lashed to the gunwales, they provide a platform for several stringers and often a keel, all of which act as the resting points for the skin rather than the ribs themselves (Figures 1, 2, and 6). The positioning of the stringers changes the points at which the skin covering touches the frame, thus changing the shape of the hull and its stability. The number of stringers used in a frame is quite variable; in general, the rounder the hull, the more stringers are required to prevent the skin from resting on the ribs. For example, most Greenlandic hulls only have two stringers and a strong keel; this creates a triangular hull with two extra points of stability (Golden 2006). Other regions have hull shapes that range from perfectly round to perfectly flat (Arima 1975:113; Golden 2006). Although the stringers are essentially bent around an extant frame created by the gunwales, crosspieces, and ribs, they must be strong enough to bear variable pressures during use. As with the gunwales, the stringers need to run the entire length of the kayak and are likewise ideally made from wood that is as straight-grained and knot-free as possible. Stringers, like gunwales, are often composed of different sections (e.g., Bergsland 1991: 179).

Overview of material selection

For all stages of kayak construction, the wood has to meet certain common criteria. All parts of the frame require wood that is as knot-free and straight-grained as possible—or in the case of cambered crosspieces, wood whose grain already bends naturally in a desired way. Selecting the right wood is key to building symmetrical and structurally sound kayaks. Even where structural components, such as gunwales, had to be assembled from many segments, builders sought pieces that could match each other.

Conclusion

Wood varies considerably in its availability throughout the Arctic, yet its use shows much continuity among Inuit and related peoples. Claire Alix (2007) has noted much similarity in the terminology that differentiates the utility of different types of wood. In Yup’ik communities in Alaska, the word unarciaq describes straight-grained wood that can be used for most carpentry tasks outlined in this article. The same qualities are described by comparable words such as unaarsivik that exist as far away as West Greenland (Alix 2007: 386-388; Petersen 1986).

This article has been limited to the selection of suitable wood for kayak construction and thus leaves out many other factors, such as the diverse carpentry tools of kayak builders. However, certain core tasks defined kayak carpentry in general. When kayak builders looked for driftwood or other sources of wood, the value they perceived in one piece over another would have been very similar across the Arctic. Kayak construction involved complex carpentry tasks, which many different Arctic peoples performed, and criteria for wood utility were further defined by many other shared technologies, such as those for the making of umiaqs, bows, sleds, harpoon shafts, and so on. Finally, by demonstrating the relationship between carpentry challenges and wood selection in kayak construction, this article shows how experimental archaeology can further our understanding of how Arctic peoples used wood throughout history and prehistory.

Appendices

Acknowledgments

I would like to express my appreciation to Pauline Knudsen and Anne Bahnson for helping me to access and photograph collections at Nunatta Katersugaasivia (Greenland National Museum) and Sisimiut Katersugaasiviat respectively. I would also like to thank Martin Appelt, Bjarne Grønnow, Hans Christian Gulløv, and Ulla Odgaard for their help and hospitality while working at SILA in 2010. Claire Alix and two anonymous reviewers were also very helpful in their discussion of kayak carpentry, as well as Debra Foran for the French translation. Research was funded in part by the Northern Scientific Training Program, the Social Sciences and Humanities Research Council of Canada, and the Department of Anthropology at the University of Toronto.

References

- ALIX, Claire, 2007 Ethnoarchéologie de la production des objets en bois dans l’Arctique nord-américain, in S. Beyries and V. Vaté (eds), Les civilisations du renne d’hier et d’aujourd’hui. Approches ethnohistoriques, archéologiques et anthropologiques, XXVIIe rencontres internationales d’archéologie et d’histoire d’Antibes, Antibes, Éditions APDCA: 377-391.

- ALIX, Claire, 2009 Driftwood, Timber and Shrubs! Wood Used by Ruin Islander Thule at Skraeling Island, Eastern Ellesmere Island, Canada, in B. Grønnow (ed.), On the Track of the Thule Culture from Bering Strait to East Greenland - Papers in Honour of Hans Christian Gulløv,Studies in Archaeology and History, Copenhagen, Danish National Museum: 149-166.

- ALIX, Claire and Karen BREWSTER, 2004 Not All Driftwood is Created Equal: Wood Use and Value Along the Yukon and Kuskokwim Rivers, Alaska, Alaska Journal of Anthropology, 2(1-2): 48-68.

- ANDREW, Frank Sr., 2008 Paitarkiutenka: My Legacy to You, A. Fienup-Riordan (ed.) and Alice Rearden (translator), Seattle, University of Washington Press.

- ARIMA, Eugene, Y., 1975 A Contextual Study of the Caribou Eskimo Kayak, Ottawa, National Museum of Man, Mercury Series, Archaeological Survey of Canada, 25.

- ARIMA, Eugene, Y., 1987 Inuit Kayaks in Canada: A Review of Historical Records and Construction, Ottawa, National Museum of Man, Mercury Series, Canadian Ethnology Service, 110.

- BERGSLAND, Knut, 1991 Aleut Kayak Terminology, in Eugene Y. Arima (ed.), Contributions to Kayak Studies, Ottawa, National Museum of Man, Mercury Series, Canadian Ethnology Service, 122: 149-166.

- BRAND, John, 1991 The Features of Aleutian Baidarkas, in Eugene Y. Arima (ed.), Contributions to Kayak Studies, Ottawa, National Museum of Man, Mercury Series, Canadian Ethnology Service, 122: 211-220.

- DYKE, Arthur S., John ENGLAND, Erk REIMNITZ and Hélène JETTÉ, 1997 Changes in Driftwood Delivery to the Canadian Arctic Archipelago: The Hypothesis of Postglacial Oscillations of the Transpolar Drift, Arctic, 50(1): 1-16.

- GILBERG, Rolf, 1974 Changes in the Life of Polar Eskimos Resulting from a Canadian Immigration into the Thule District, North Greenland in the 1860s, Folk, 16: 159-170.

- GOLDEN, Harvey, 2006 Kayaks of Greenland: The History and Development of the Greenlandic Hunting Kayak, 1600-2000, Portland, White House Grocery Press.

- GRØNNOW, Bjarne, 1994 Qeqertasussuk - the Archaeology of a Frozen Saqqaq Site in Disko Bugt, West Greenland, in David Morrison and Jean-Luc Pilon (eds), Threads of Arctic Prehistory: Papers in Honour of William E. Taylor Jr., Ottawa, National Museum of Civilization, Archaeological Survey of Canada: 197-238.

- GRØNNOW, Bjarne, 1996 Driftwood and Saqqaq Culture Woodworking in West Greenland, in Cultural and Social Research in Greenland 95/96. Essays in Honour of Robert Petersen, Nuuk, Ilisimatusarfik Atuakkiorfik: 73-89.

- GULLØV, Hans Christian, 1997 From Middle Ages to Colonial Times. Archaeological and Ethnohistorical Studies of the Thule Culture in South West Greenland 1300-1800 AD, Copenhagen, Danish National Museum.

- HOADLEY, R. Bruce, 2000 Understanding Wood: A Craftsmen’s Guide to Wood Technology, Newtown, Taunton Press.

- LARSEN, Helge, 2001 Deering - a men’s house from Seward Peninsula, Alaska, edited by M. Appelt, Copenhagen, SILA - The Greenland Research Center and National Museum of Denmark, Ethnographical Series, 19.

- MELDGAARD, Morten, 2004 Ancient Harp Seal Hunters of Disko Bay: Subsistence and Settlement at the Saqqaq culture Site Qeqertasussuk (2400-1400 BC), West Greenland, Copenhagen, Danish Polar Center, Meddelelser om Grønland/Monographs on Greenland, Man and Society, 30.

- NANSEN, Fritjof, 1893 Eskimo Life, London, Longmans.

- PETERSEN, Hans Christian, 1986 Skinboats of Greenland, Roskilde, Viking Ship Museum, National Museum of Denmark, and Museum of Greenland, Ships and boats of the North, 1.

- TREMBLAY, L.-B., L.A. MYSAK and A.S. DYKE, 1997 Evidence from driftwood records for century-to-millennial scale variations of the high latitude atmospheric circulation during the Holocene, Geophysical Research Letters, 24(16): 2027-2030.

- WALLS, Matthew, 2010 Paleocarpentry in the Eastern Arctic: An Inferential Exploration of Saqqaq Kayak Construction, vis-à-vis: Explorations in Anthropology, 10(2):96-109.

- WHEELER, Robert and Claire ALIX, 2004 Economic and Cultural Significance of Driftwood in Coastal Communities of South Western Alaska, report, Fairbanks, University of Alaska Fairbanks, Cooperative Extension Services.

- WHITRIDGE, Peter, 1999 The Construction of Social Difference in a Prehistoric Inuit Whaling Community, Ph.D. dissertation, Arizona State University, Tempe.

- ZIMMERLY, David, 1979 Hooper Bay Kayak Construction, Ottawa, National Museum of Man, Canadian Ethnology Service, 53.

List of figures

Figure 1

Four general stages of construction shared by kayaks from across the Arctic: 1) gunwales; 2) crosspieces; 3); ribs; 4) stringers and keel

Figure 2

General aspects of kayak frames

Figure 3

Tensile pressures in gunwales and importance of grain selection

Figure 4

The importance of equalising both gunwales

Figure 5

Examples of composite gunwale strakes: a) a Netsilik kayak collected by the 5th Thule Expedition (photo: courtesy of the Danish National Museum, item P30 161); b) from the Illorpaat site in West Greenland (see Gulløv 1997: 147) (photo: courtesy of the Greenland National Museum, item IGD 3696); c) from an archaeological site at Nordbø, South Greenland by H.C. Petersen (photo: courtesy of the Greenland National Museum, item KNK 171); d) a piece of the Morris Bay kayak, from Washington Land, North Greenland (see Mathiassen 1928) (photo: courtesy of the Greenland National Museum, item KNK 122). All photos by Matthew Walls

Figure 6

Interior of a Greenlandic kayak: a) cambered crosspiece mortised securely to the gunwale; b) cambered crosspiece mortised securely to the gunwale; c) ribs mortised to the gunwale; d) stringer held in position by the ribs. Photo: courtesy of the Danish National Museum, item Lc. 148, photographer: Matthew Walls

Figure 7

Bending ribs

List of tables

Table 1

Greenlandic naming of wood types with descriptions (after Petersen 1986: 18-19)

Table 2

Comparison of names for the four structural components of a kayak. The phonology is not standardised and terms are left in their source format