Résumés

Summary

This article uses time-series data from two aluminium plants from Canada and the U.K. to analyze the social relations of productivity. The eventual turn to teamwork reflected, not hard evidence that productivity change had dried up, but a belief that they were the next step towards further improvement. By considering the structure of social relations over time in each smelter, we contribute to ongoing debates on the complex connections between productivity growth and organizational innovation. On the basis of direct observation and interviews, the article also reveals some of the social dynamics generating productivity growth and describes the development of idiosyncratic competencies. It stresses how the development of teamwork was historically in line with the productive ethos that had developed over time under continuous process technology.

Résumé

Cet article, basé sur une étude empirique dans deux alumineries de la société Alcan, se situe dans le courant de recherche sur les équipes de travail et sur les « systèmes de travail à haute performance ». Il se démarque cependant des approches orthodoxes du point de vue de la méthodologie en s’appuyant à la fois sur une série de données longitudinales et sur une étude de terrain en profondeur. Il vise ainsi comprendre l’évolution de la productivité et des rapports sociaux dans chacune des usines sur une longue période. En considérant aussi l’effet de la technologie et la nature du travail, il est possible de mettre en lumière certaines des raisons qui sous-tendent les changements apportés à l’organisation du travail et d’apporter une contribution sur le plan théorique.

Il est possible de considérer à la fois l’évolution de la productivité et celle des rapports sociaux de travail en s’appuyant sur deux techniques de recherche complémentaires. L’analyse s’appuie d’abord sur une série complète de données sur la performance des usines Isle-Maligne et Lynemouth sur une période 20 ans, soit de 1973 à 1992. Ces données sont celles qui furent transmises au siège social par chacune des usines, à chaque mois. L’accès à de telles séries de données est assez rare et le texte précise les possibilités et les limites de celles-ci pour les fins de la recherche. Dans cet article, l’analyse porte sur les deux mesures les plus pertinentes pour évaluer la productivité du travail. L’interprétation de ces données est favorisée par une étude de terrain en profondeur dans chacune des alumineries, suivant une approche ethnographique basée sur l’observation directe du travail et différents types d’entrevues auprès de toutes les strates sociales dans l’organisation. Notamment, l’un des auteurs a effectué 40 jours de terrain en 1992–93 dans l’usine située dans la région du Lac-Saint-Jean, maintenant remplacée par une aluminerie moderne, et des entrevues de suivi ont aussi été réalisées au cours des années suivantes.

Le texte est structuré autour de deux questions complémentaires. Il vise premièrement à cerner les conditions objectives ayant incité la direction de chacune des alumineries à implanter des équipes de travail. Les données longitudinales montrent que la croissance de productivité fut considérable durant la majeure partie des années 1980 mais qu’elle eut tendance à perdre son rythme durant les années précédant l’implantation des équipes. Cet épuisement de la croissance de productivité, ainsi que l’intensification de la concurrence sur le marché mondial de l’aluminium de première fusion, incitèrent la gestion à innover au point de vue organisationnel. Comme ces deux usines n’étaient pas à la fine pointe sur le plan technologique, il s’agissait de pousser à la limite les possibilités des équipements en opération eu égard à l’efficience.

Cette analyse conduit à la seconde question de recherche, qui a trait au développement des qualifications tacites et des compétences spécifiques à ce type de travail. Dans les deux cas, une main-d’oeuvre ayant acquis beaucoup d’ancienneté montrait une capacité et une volonté de travailler de façon plus autonome, en mettant à profit leurs connaissances du métier. Tant dans l’aluminerie située au nord de l’Angleterre que dans celle située au Québec, cette conscience et cette fierté de producteurs favorisaient la prise en charge collective de l’activité de production. Toutefois, cette capacité d’autorégulation ne signifie pas pour autant que la division sociale entre les salariés et la direction soit atténuée. Au contraire, une indépendance bien sentie des salariés et de leur syndicat à l’égard des gestionnaires constitue un autre trait marquant de la conscience ouvrière dans les deux cas. Cette indépendance représente justement une autre condition pouvant conduire à des formes plus autonomes d’organisation du travail.

Bien que l’implantation des équipes de travail ait rencontré certaines difficultés, surtout dans le cas de l’usine québécoise où ce développement allait à l’encontre d’une autre logique bien intériorisée, celle du marché interne, cet article met en lumière la continuité historique entre l’organisation traditionnelle du travail dans ce secteur et la conception moderne des équipes de travail. L’autonomie au travail et la cohésion sociale étaient là bien avant la réflexion du management sur les équipes de travail. Une telle continuité paraît favorable à plusieurs égards, dont celui de l’efficience organisationnelle. De façon plus générale, cette étude suggère que le management a souvent avantage à concevoir et à adopter des innovations qui vont dans le sens de l’histoire, celle de l’organisation concernée, plutôt qu’à rechercher des solutions universelles ou des modes de gestion qui sont contraires à l’évolution des rapports sociaux.

Resumen

Este artículo utiliza los datos de ciclos de tiempo provenientes de dos plantas de aluminio situadas en Canadá y Reino Unido con el fin de analizar las relaciones de productividad. La conversión al trabajo en equipos no mostró gran evidencia de estancamiento de productividad sino mas bien la idea que los equipos fueron un paso adelante hacia mejoras adicionales. Considerando cómo las relaciones sociales estructuran el tiempo en cada fundición, nuestra investigación contribuye al debate en curso sobre las conexiones complejas entre el crecimiento de la productividad y la innovación organizacional. Sobre la base de la observación directa y de entrevistas, el artículo revela también en parte las dinamicas sociales que generan el crecimiento de la productividad y describe el desarrollo de competencias idiosincraticas. Esto muestra como el desarrollo del equipo de trabajo se encuentra en continuidad historica con el ethos productivo que se ha desarrollado a través del tiempo con la tecnología de proceso continuo.

Corps de l’article

It is increasingly argued that productivity is shaped, not just by the technical organization of capital and labour, but also by social relationships. At the level of countries, Crouch and Streeck (1997: 3) for example distinguish market-driven economies from “institutional” ones in which economic activity is regulated by mechanisms additional to markets; they note that many analysts have “confidently” asserted the performance benefits of the latter. Within the firm, systems of work organization, variously labelled as High Commitment, High Performance or High Involvement practices, have been a central feature of recent debates in North America (Ichniowski et al. 1996; Appelbaum et al. 2000; Murray et al. 2002) and Europe (Sisson 1997; Ramsay, Scholarios and Harley 2000). Definitions vary widely, but in essence such a system will entail the delegation of authority to work groups and an increase in their autonomy. We will use the label of High Involvement Work Systems (HIWSs). One strand of research has examined the effects of these systems on the performance of firms and on workers’ job satisfaction and commitment (Appelbaum et al. 2000). A second has examined reasons for their implementation, in the face of the widely noted paradox that the systems “work” and yet have relatively low rates of adoption in countries including the U.S. (Cappelli et al. 1997) and the U.K. (Cully et al. 1999).

This article addresses the second issue but also steps outside the specific debate on high involvement systems, for several reasons. First, a widely noted limitation of much of the evidence is its cross-sectional nature (Becker and Gerhart 1996). This leaves open issues such as reciprocal causation: do the “outcomes” determine the adoption of HIWSs, for example because successful firms are able to afford the costs involved, rather than the reverse (Godard and Delaney 2000; Purcell 1999)? Second, many HIWS studies tend to see the workplace as essentially harmonious; by contrast, we need to view any system of work organization as in principle contested. Third, and relatedly, there is a curious neglect of earlier studies of social relations of work, notably the studies of trade unions and productivity (Freeman and Medoff 1984) and of the history of labour relations on the shopfloor (Lazonick 1979; Elbaum and Lazonick 1986). This is particularly ironic given that the HIWS literature has arrived at a point similar to that which the unions and productivity debate reached before it was supplanted: that debate concluded that it is not unions as such which are crucial but the specific nature of their interaction with management (Freeman and Medoff 1984: 179). Similarly, after years of quantitative study, the HIWS literature concludes that there is no invariant link between systems and outcomes and instead that the “idiosyncratic competencies” within individual firms are the key (Becker et al., 1997). As Purcell (1999) notes, this brings it in contact with the established resource-based view of the firm. What, then, are the competencies and resources that may be mobilized in the pursuit of productivity? We need to study the shopfloor to find out.

This article looks at the development of productivity within one firm over a period during which the firm introduced work practices that are often included in lists of high performance practices, notably teamwork. Both the reasons for the introduction of teamwork and the shaping of productivity in pre- and post-team periods reflected social processes which are not captured in the high involvement debate. The study uses evidence over a twenty-year period from two aluminium smelters. The data are based on physical measures of a standardized product, so that we can be confident that productivity is consistently and appropriately measured. The importance of this is that attempts to find “union” effects in the older literature and to find “HIWS” effects in newer work have often been criticized for using measures of the financial performance of firms: such measures conflate efficiency in the workplace and the ability of firms to raise prices in the market place (Nolan and Marginson 1990). Physical measures remain rarely used, and we follow the approach of studies such as those by Clark (1981) from the earlier work on unions, Ichniowski, Shaw and Prennushi (1997) from the later HIWS debate, and Kleiner, Leonard and Pilarski (2002) who combine elements of both. The difference is that these studies generally focus on quantitative data while the present concern is more with the social dynamics generating productivity change. In short, we deploy extensive fieldwork evidence to understand the evolution of social relations over time and thus explain why teams were adopted even though productivity in the pre-team era was increasing and why managerial policy shifted in favour of teams.

The article pursues two related objectives. First, we study the context and the conditions of implementation of teamwork. By considering also the structure of social relations over time in each smelter, we contribute to ongoing debates on the complex connections between productivity growth and organizational innovation. Second, also on the basis of direct observation and interviews, we aim to reveal some of the social dynamics generating productivity growth and to describe the development of idiosyncratic competencies. By this we refer to the tacit skills and organizational routines on which firms have to build in order to improve efficiency. We stress in particular that the development of teamwork was historically in line with the nature of work and the forms of group cohesion which had developed over time under continuous process technology.

After a presentation of the complementary research techniques applied here, the trends in productivity over two decades are presented in a first empirical section. The following section contributes to the understanding of these trends by exploring in some detail the evolution of workplace relations in the two smelters during the period leading to the introduction of teams. The changes observed in the following years are then discussed briefly in a final empirical section, which leads to the conclusion.

Data and Methods

We studied two plants owned by the Canadian-based company Alcan, the world’s second largest producer of aluminium, behind the U.S. giant Alcoa. The core of Alcan’s business is the smelting and rolling of the basic metal. One Canadian smelter, at Isle-Maligne in Quebec, was studied. It was compared with a U.K. plant, at Lynemouth in the north-east of England.

The two plants shared many characteristics. The heart of an aluminium smelter is the pot room, where a series of pots is linked together into potlines. Each pot is charged with the raw material, alumina, which is refined from bauxite. There is a carbon anode, the body of the pot providing the cathode. An electrical current is passed through the pot until the alumina is reduced, at which point the molten aluminium is “tapped” from the pot and sent to be cast into ingots. Aluminium is also a decidedly long-term business in view of the massive investment, of more than U.S.$ 1 billion, required to build a new smelter. The large capital costs mean that management has little flexibility to open and close plants at short notice, and must focus upon improving existing operations.

Although the method of producing aluminium is relatively standard, these smelters utilized different generations of electrolysis technology. Isle-Maligne used the older Söderberg system, with a carbon paste as the anode; Lynemouth had the pre-baked system in which, as the name implies, a separate carbon anode is baked into a block and then positioned in the pot. A second key difference is the source of energy, for energy costs comprise a large proportion of the costs of producing aluminium. Isle-Maligne had the benefit of cheap hydro-electricity (whose presence was the reason for the original development of Alcan in Quebec). Lynemouth used coal as its energy source, and had its own coal-fired power station; coal is a relatively expensive fuel. Because these two smelters did not use the same generation of technology, we cannot compare absolute levels of productivity. We can, however, compare trends over time. The social organization of work is similar, with teams of workers working on the standard tasks of charging, monitoring and tapping the pots. Work in both plants was organized on a round-the-clock basis using 12-hour shifts. Workers divided their time between “on-line” activities servicing the pots, and “off-line” periods spent recuperating in the rest room. Production workers at the two plants were also unionized, with virtually 100% membership.

Pressures for change in the workplace emerged from the erosion of the oligopoly enjoyed by the large firms until about 1980, together with the trading of aluminium on the London Metals Exchange, which encouraged price volatility and in turn put pressure on operating costs (Nappi 1994: 66-67; Bélanger and Dumas 1998). This context had a profound impact on the two plants under investigation. At Isle-Maligne one of the three potlines was temporarily shut down for a ten-month period from November 1991. The plant employed 408 staff at the time of the fieldwork in 1992–93, down from 677 in 1980. Several years after the period of observation, the plant was closed and replaced with a new smelter built in the same small town, to which its workers were transferred. The story of Isle-Maligne is of successfully maintaining the plant in operation so that workers collectively saved their jobs in the new operation (Bélanger 1999). The Lynemouth smelter closed one of its two potlines, Line 1, in 1991, laying off approximately half the workforce. (In U.K. parlance the workers were made redundant, with no expectation that they would be re-hired, though a few did rejoin the plant). Before this major event, the plant had 695 employees, a number which fell to 350 by 1995.

Research methods were primarily qualitative. One author spent 40 days in observation and interviewing at Isle-Maligne between 1992 and 1993. Follow-up visits were made in 1994 and 1995. The other two authors studied the Lynemouth smelter in 1995 for a total of 30 person-days of visits, each which included interviewing and observation, together with the distribution of a questionnaire to 31 employees. A follow-up visit was made in 1997. The three authors also jointly interviewed senior executives at Alcan headquarters in Montreal, in 1996. Each study focused on the performance of work tasks, the organization of work within teams, and the reasons for and effects of the introduction of teams. By the mid-1990s, the plants had broadly similar systems, in which the previous command-and-control system of direct supervision was replaced with work teams which had autonomy in the allocation of work tasks.

Alcan takes over forty measures of process performance at monthly intervals in each of its plants around the world, using definitions that remained unaltered throughout the time of study. We examine two primary indices for the period 1973–1992, which Alcan managers see as key to assess the impact of labour utilization on productivity. The first is, in Alcan’s terminology, man hours per metric tonne (MHMT), which is the number of hours worked in the potrooms, divided by the output of aluminium. It measures labour efficiency. The second, net kilograms of aluminium per pot per day (ALPD), measures capital utilization. Data used here are annual. At Lynemouth, data refer to Line 2 only between 1972 and 1994. For Isle-Maligne, the data shown are the mean for the three potlines between 1970 and 1992. Data on another key input, the level of training, will also be presented. Low labour turnover means that we are looking at a largely fixed stock of workers so that issues of changing worker human capital do not arise. Such conditions allow us to examine the social relations of production with unusual precision.

It is worth being more specific on the strengths and limitations of this data set. These are the data actually used by plant and corporate management to assess performance and the basis of measurement remained constant over time. These are “absolute” or “physical” measures, as opposed to measures of relative productivity. However, because the two smelters under study are not of the same generation of electrolytic technology, the researcher has to be careful not to build the analysis on the basis of a strict comparison of these physical measures. Indeed, unlike some multinational corporations where technologies are more similar, and less capital intensive, Alcan managers are used to make comparisons between what they call “families of plants,” i.e. smelters of the same generation of technologies, and indeed with similar levels of capital investment.[1] This is why we are prudent in discussing the evolution within each plant over time and then in proceeding to a comparison of patterns of change between the two plants. Our analysis is based on the measures which are seen by management as the more telling regarding labour productivity. Longitudinal data on actual measures of productivity are relatively rare in the literature. In so many sectors, such a robust and constant set of data over time simply does not exist. And when it does, these hard data tend to be seen, rightly, as confidential and sensitive. Things are made easier here because the data we discuss are not so recent, they are retrospective.

Trends in Productivity

Man hours per metric ton (MHMT) is the most direct indicator of productivity because it is calculated on the basis of the number of hours paid to the production (or hourly) workers assigned to the potrooms during the period of reference. It includes overtime and does not consider any loss of working time due to absenteeism or any other reason.

Productivity Data

Figure 1 shows MHMT for the two plants. Two points are immediately evident. First, there was a sustained decrease in MHMT of a similar magnitude at both smelters during these two decades. Since Lynemouth commenced full production only in 1973, we take 1975 as a base. Between 1975 and 1992, MHMT improved by 39% at Isle-Maligne and by 38% at Lynemouth. These improvements are particularly notable at Isle-Maligne, for the plant was established in 1943 and one might expect that the intervening 30 years would have exhausted the productivity potential of the technology. The fact that productivity continued to grow illustrates the social and organizational determinants of efficiency: there was no significant capital investment and productivity changes reflected mainly the ways in which labour was deployed. Second, this growth was concentrated in the period prior to the introduction of teamworking in 1991. This plainly runs counter to arguments that high involvement is stimulated by the poor performance of the previous system.

Figure 1

Man Hours per Metric Tonne

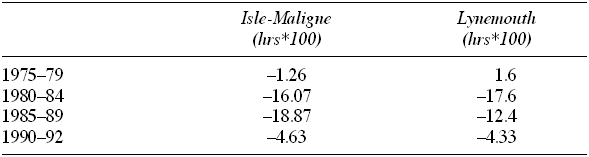

Between 1980 and 1987, MHMT diminished, a trend which accelerated between 1987 and 1990. Columns 1 and 2 of Table 1 show mean annual change in MHMT, at five year intervals, and for the three year period 1990–92. At both smelters, the years of relative stagnation in MHMT were 1975–79, followed by a period of sharply diminishing costs, in 1980–84 and again in 1985–89.

This finding is further reinforced by considering the second indicator, net kilograms of aluminium per pot per day (ALPD). While MHMT expresses output in relation to the number of hours worked, ALPD is the ratio of output for each pot, or unit of functioning capital in operation. Pots have a finite length of service, beyond which they require refurbishment. They are also subject to random “bursts,” which are difficult to predict. Obviously, the number of days for which each pot is able to produce aluminium will affect the total output which may be realized from the smelter in any one year.

Table 1

Mean Annual Change in Man Hours per Metric Tonne (MHMT)

Note: Figures for mean annual change multiplied by 100, for ease of presentation.

Mean Annual Change is calculated as:

where Xy is the index in the present year, Xy-1 is the index in the preceding year, and N is the total number of years in that period.

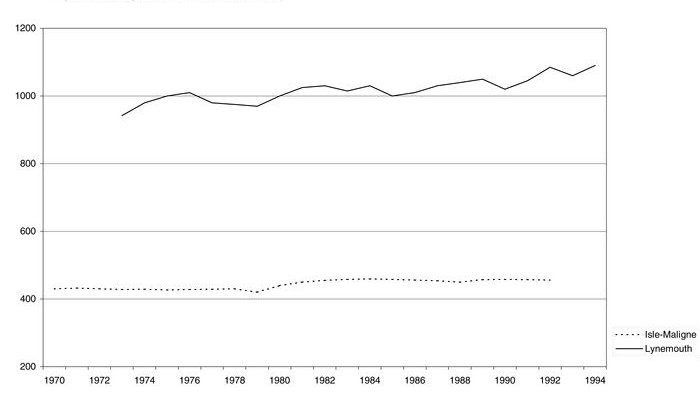

Figure 2

Net Kg aluminium per Pot per Day

Data for ALPD are shown in Figure 2. Two features stand out. First, the absolute level of capital efficiency is much higher in the newer plant at Lynemouth than at Isle-Maligne. Second, the rate of increase over the study period is relatively slight, in the order of 7.9% at Lynemouth and 1.5% at Isle Maligne. This may reflect the difficulties of significantly raising the performance of the technical system, compared with the utilization of human assets.

As for performance in the years 1990–92, when teamworking was introduced, it is widely expected that there may be short-run falls in productivity because of the destabilization of routines caused by changes in work organization (Pil and MacDuffie 1996). Figure 1 shows, however, that MHMT fell at both smelters. Table 1 shows that the mean annual change in MHMT for the period 1990–92, at both smelters, was considerably below that for the period 1985–89. Hence, the evidence suggests that the pace of improvement continued but at a slower pace at the time that teams were first implemented.

Training

As noted above, some authors propose that complementary HR practices might smooth the introduction of high involvement systems. A commonly used indicator is the degree of attention to training. Data on the annual number of hours spent on training are set out in Table 2. The level of training at both smelters fell between the period 1975–79 and 1980–84. This trend is contrary to the two performance indicators, each of which improved substantially during the early 1980s. At Lynemouth, the periods of rapid advance in MHMT, between 1980–89, correspond with the lowest levels of time spent on training. The argument that the output growth of the 1980s derives from an increase in system inputs, in the form of training, finds little support here.

Table 2

Mean Hours Spent on Training

Note: Figures for Lynemouth are for Line 2; for Isle-Maligne, figures quoted are the mean hours spent on training on each of the three lines (i.e., total training divided by 3).

The introduction of teamworking was paralleled by an increase in levels of training at Lynemouth. At Isle-Maligne, the level of training was much increased during the 1985–89 period when new ancillary equipment was introduced, and then remained at the same level in the early 1990s. A commitment to training may have preceded the introduction of teams at Isle-Maligne but not at Lynemouth. Overall, training may be a component of a HIWS but its association with productivity is variable.

Changes in Work Organization: The Pre-teamwork Era

How can this record be explained? We first indicate lasting features of the two sites that contributed to productivity growth. We then deal with the specific processes within each plant in turn.

Social Relations of Production

Work in a smelter has always been based on crews of workers co-operating on work tasks. It shares with coal mining and steel many characteristics that have long been recognized to generate work group cohesion (Seashore 1954; Hill 1974). Organization into 12-hour shifts removes workers from the conventional routines of labour from Monday to Friday. A worker could be expected to start a shift at 7 pm on Christmas Day without complaint. This system itself produces mutual dependence, since anyone going absent at such a time would have to be replaced by a colleague and would scarcely be popular. Absence rates at both smelters were indeed low. Data from Lynemouth for example point to a frequency of absence of under half of that in manufacturing in the U.K. generally (Wright and Edwards 1998). The work was well-paying and, as we have noted, labour turnover was very low. Further heightening this sense of cohesion was the geographical isolation of the plants. Isle-Maligne was located in a region dominated by Alcan sites, which pay wages well above the regional average. Lynemouth was in an area traditionally dominated by the coal industry, which was in rapid decline and which left the plant as one of the few “good” employers in the area. Cohesion was also enhanced by the gender composition of the work force. All manual workers, supervisors and technicians were men, and the heavy, hot and dangerous nature of the work helped to develop a “macho” self-image. This broad cohesion was reinforced through the organization of work. Workers have long been organized into work crews each of which has the responsibility for a set of tasks on a group of pots. Each crew arranges the tasks so as to share out the least desirable operations, notably the hot and dirty work of cleaning waste product from under the pots. When a series of tasks has been completed, workers retire to the relative calm of rest rooms. Teams developed into cohesive units.

Workplace sociology has long recognized that group cohesion can promote pro- or anti-productivity attitudes. On a typical assembly line, there is the potential for endless disputation about the speed of the line and the job responsibilities of individual operators. Output also depends centrally on how rapidly workers are working, and supervisors typically devote energy to ensuring that workers meet daily output targets (as described in studies of classic Fordist conditions, e.g. Beynon 1973, and also Japanese lean production, as for instance in Graham 1995). A smelter does not work in this way. There is an alternation between periods of work and leisure, and the work itself is not the repetitive completion of identical operations. Moreover, production is relatively predictable in the short-term so that, in contrast to much assembly work there is little fear that rising output will directly lead to job cuts, a fear that has been identified at least as far back as the Hawthorne studies.

When there is “chaos on the shopfloor” (Juravich 1985), distrust will grow. The smelters were not organized chaotically. They were producing a single product, and thus did not have problems of frantic changes in product mix that are common in assembly plants, and work was predictable. In these circumstances, together with a high level of job security, worker cohesion did not lead to restrictivism, even though it did not lead to high levels of trust either. This interpretation is supported by the very similar results from a study of a pharmaceuticals plant in Ireland (Geary and Dobbins 2001).

If this explains why productivity was not resisted, what of the dynamic that produced improvement? Our observation in the 1990s highlighted efforts to squeeze more efficiency out of the equipment. The plants had cadres of technical specialists whose role was to reduce downtime and improve product quality, and they were constantly tinkering with the many variables in the production of aluminium. For example, increasing the heat of the pot speeds the process but at the cost of greater fuel usage and the risk of burning out the pot linings. Learning on the job is likely to have been significant, even in a “mature” technology. We spoke with technicians whose major function was, for example, to tinker with the mix of the ingredients of an anode and the cycle time of its production. Such activity went on constantly, and was underpinned by more periodic improvements. For example, the linings of the pits in which pre-baked anodes are made require periodic renewal. Alcan has technologists with specific expertise in the design of linings, and efforts to improve design were continuous. Some of the relevant changes would bear directly on labour productivity. For example, if a lining’s life can be lengthened then less labour is needed because renewals are less frequent. In this case, labour input is reduced rather than there being a rise in effort. Within these general conditions, matters in the smelters varied, as we now show.

Isle-Maligne

In the early 1990s, the period in which teamwork was implemented, we observed a growing co-operation between plant management and the local union to make the best out of an outmoded technology in order to save jobs. But these developments can only be understood in the context of earlier periods. Alcan constructed this smelter in 1943. The workplace union representing all manual workers was recognized in the following years. Interviews with senior employees indicate that physical working conditions were very difficult in the early years. Extremes of heat, fumes and dust were damaging to health and safety. As documented by Lapointe (1992) in a longitudinal study of another Alcan smelter in the same region using similar technology, these working conditions were tolerated in exchange for relatively high wages. The work rules associated with seniority also meant that workers had some job security and protection against favouritism. Yet there was only an arm’s length exchange of pay for effort, and shopfloor relations were tense. In these and other Alcan smelters located in the same region, there were two major strikes, of six months in 1976 and four months in 1979. Stoppages are particularly serious in the aluminium industry because of the damage that can be done to pots when they are allowed to cool and the time taken to restore them to operating efficiency. As Figure 1 shows, this pattern of strikes in the 1970s a detrimental effect on productivity; Kleiner, Leonard and Pilarski (2002) using much richer data on this matter demonstrate a similar result. More generally, the productivity trend during this period of antagonism was flat.

The long period of open conflict led management and unions to make a major shift in their approach to labour relations, with the reopening of the collective agreements in 1981 now being considered as the turning point (Lavallée 1993: 152–153). In the following years, both sides took part jointly in training programmes on the bargaining process. This new approach to bargaining apparently worked; there was no strike for several rounds of negotiation. It was at this time that the subject of teamworking was initially raised. The unions insisted that their members knew how to make the potlines work efficiently. Management, they meant, only had to stop being authoritarian and let them work as they saw best. However, concrete effects on the shop floor were longer in coming.

Isle-Maligne, because of its outdated technology, was perceived to be in a particularly vulnerable position. The reaction to the temporary closure of one of the three potlines in November 1991 proved to be a turning point, taking place as it did in the context of overproduction and falling prices. Approximately 200 workers agreed to participate in a Canadian federal government programme of work sharing, in which they consented to a reduction of their working hours in order to avoid lay-offs. This arrangement evolved into a broader attempt to ensure the plant’s viability. In 1992, the management team submitted a series of recommendations to the parent company aimed at re-vitalizing the plant on the basis of what was termed a pacte social, which stressed co-operation in securing the future of the plant though reducing costs and finding new market opportunities. It was endorsed by the union general assembly, which focused on the chance of securing jobs at the plant.

When we conducted in-depth fieldwork in 1992–93, the situation had already changed considerably. The introduction in 1988 of small air-conditioned vehicles had much reduced exposure to harsh conditions. This allowed workers to carry out some tasks of tapping pots, which were previously performed manually and which exposed workers to heat and dirt. This innovation had a substantial influence on productivity, by reducing manning levels and increasing the proportion of working time that could be spent productively rather than recovering in the rest rooms. At the time of fieldwork, the agenda was to push this out-dated technology to its utmost in order to counteract any corporate intention to close the plant, in a context of very low prices and overproduction worldwide. But further efficiency improvements could only come from social organization. Although the support of workers and their workplace union for the pacte social was somewhat ambivalent, it was a key element in helping plant management to gain support for their program of action from Montreal headquarters. It is in this context that teamwork was being implemented in the early 1990s.

Lynemouth

For the period from 1975 to 1990, Lynemouth illustrates how incremental change can be carried through. All our interviewees were clear that the smelter did not share the antagonistic industrial relations that, they felt, marked much of British manufacturing during the period. The plant had only one strike of any significance. It was also not troubled by disputes between different unions that affected sectors including autos and shipbuilding: the plant had, and has, only one significant shopfloor union, the General and Municipal, with other unions having very much a junior role. From its inception the plant had no established demarcations among craft workers. As several of our interviewees stressed, in much of British industry electricians and mechanical maintenance fitters had well-established job boundaries, the effects including disputes over job territory, particularly when new products were introduced, and an inflexibility in work practice so that an electrician would not touch a job until the fitter had created access to electrical equipment (see, for example, Edwards and Scullion 1982: 214–221). At Lynemouth, the absence of any new products removed one such source of dispute but more fundamentally the plant had been designed to operate relatively flexibly, so that each craft group would carry out any activity within its competence.

Direct evidence from the period is a study carried out in 1985 at the request of management and unions, which included 228 interviews with managers and workers (Musgrave 1986). The author stresses that he had visited “many plants” where industrial relations was “much worse” than at Lynemouth but argued a need for further change. This reflected, first, external conditions. Plant management spoke of the need to “remain competitive” with other plants in the group, some of which had newer technology. International competition had dictated the need “to cut costs to remain viable,” and divisional management thought Lynemouth’s performance was “not picking up quickly enough.” Management set a goal of improving productivity by 20% over the five years from 1985, with an emphasis on reducing manning levels. As for relations within the plant, shopfloor workers expressed distrust of, and alienation from, management. Musgrave found that employees throughout Lynemouth “appear to have lost faith in management.” The sophisticated management style of the Canadian managers under whom production had started in 1972 had been lost. The outcome was a general feeling of demotivation and insecurity. Musgrave made a number of recommendations for the improvement of industrial relations, the broad themes of which foreshadow the reforms that were eventually introduced. For example, management must become more committed to genuine consultation and communication, team briefing was to be introduced, and supervisors were to be given training in briefing and leadership skills. However intellectually valid such arguments may have been, however, there was little incentive to apply them, and it took the shock of job losses five years later for them to find a receptive environment.

The evidence of Figure 1 suggests that efforts to improve productivity during the late 1980s were successful. The route taken seems, however, to have focused on manning reductions and tight control rather than teamwork. Improvements in consultation and involvement were not substantially introduced until the 1990s. Research on manufacturing industry as a whole during this period identifies a re-assertion of managerial prerogative and an increase in levels of work effort (Elger 1990). Lynemouth is likely to have been part of this trend. Certainly, workers interviewed in 1995 spoke of assertive and autocratic managerial styles during the 1980s.

Conclusions

Building on the material conditions described above, managements and workers at both smelters sought a more co-operative set of relationships during the 1980s. Progress was greater at Isle-Maligne but from a starting point of greater antagonism. As we have seen, overall productivity trends at the two plants were similar. The key lesson at this point is that revisions to the social organization of production went with the flow of existing arrangements and thus stood a reasonable chance of becoming embedded in the longer term.

The Introduction of Teams

Although productivity improved during the 1980s, managers in both plants were aware of tensions on the shopfloor and were concerned about their plant’s long-term viability. At Isle-Maligne, the first steps towards teamworking were taken in 1988, but these were accelerated from 1991 onwards. Two developments are of particular interest; the introduction of problem-solving groups and a move towards self-directed work teams (SDWTs). The number of supervisors was halved between 1988 and 1993, and the number of job classifications was cut from 100 to 58 during the same period. Teams were given responsibility for a wider range of functions. The aim was not to provide complete and systematic job rotation within the team. Rather, multi-skilling, whereby each worker is able to perform at least two jobs, was introduced.

The progress of SDWTs was quite variable, and the employee response was often equivocal. Some workers preferred the specific job assignments of the pre-team era. Other problems concerned the definition of the role of remaining supervisors, who now had to act as “coach,” and workers’ demands for additional pay in return for extra responsibilities. The local union was a little ambiguous in its defence of teamwork, and members of the executive committee felt the resistance and loud criticism coming from some of their members was difficult to withstand. In short, there was a growing tension between two different models of work regulation, the previous pattern built upon tight internal labour market rules, and the teamworking model, built upon labour flexibility (Bélanger and Dumas 1998). Nevertheless, the organizational changes of the early 1990s helped to push to its limits the productive potential of this outdated technology. It was acknowledged by all that unionized workers had played a positive role in this process. When, in the year 2000, the plant was closed and production started in the new Alma smelter, a huge investment in the same town, workers from the old plant were covered by an agreement giving them priority of employment there.

At Lynemouth, change came much more rapidly. In 1990, a new works director and a new personnel manager were appointed. Recruited from outside the company, the personnel manager was told that “drastic surgery” was required at Lynemouth. A residential conflict management session, attended by all managers, supervisors, and shop stewards, lasted for three days and stimulated informal interaction. Teamworking was premised on the assumption that workers were over-supervised and, if correctly trained and afforded some autonomy, they could work to the required standards. Teamwork was introduced in a number of stages. In 1991, the team leader position, one of coordination but without the power to discipline other team members, was introduced. Team leaders were recruited from existing shopfloor operatives, and selected by management. At the same time, the position of “accredited instructor,” a team member responsible for training other operatives, was brought in. In 1994, direct supervision was abolished in production areas, although not in craft positions, and some fifty supervisors were made redundant. Teams were given responsibility for monitoring output, quality, safety and certain aspects of budgeting. All shopfloor operatives were trained across the full range of tasks performed by the group, except certain roles which require specialized technical skills. Workers reported having a wider range of skills and being better able to exercise them. Teamworking was instituted with the explicit endorsement of the plant’s main trade union and the chair of the union committee (convenor in U.K. parlance).

Before 1990, industrial relations remained tense at Lynemouth. Annual collective bargaining negotiations in 1989 continued for nine months. Since then, the climate of management-union relations has become more open and consensual. The evidence suggests that employees responded favourably to teamworking. Following the elimination of supervisors, workers spoke of improved job satisfaction, increased levels of interest in their work, and greater decision-making autonomy. The level of reported accidents, overtime and absence all fell.

At both plants, therefore, teamworking was a development of, rather than a sharp break from, previous patterns of work organization. It did not accelerate productivity improvement, but it did alter the climate of workplace relationships and demonstrate that new forms of work organization could be implemented.

Conclusions

This article uses time-series data and direct observation in two plants from Canada and the U.K. to analyze the social relations of productivity. Both plants adopted parts of the HIWS model, such as teamwork, but even before this adoption productivity was increasing. The eventual turn to teams reflected, not hard evidence that productivity change had dried up, but a belief that they were the next step towards further improvement. The reduction in productivity growth may have played a role in suggesting that organizational change had to be implemented. Considering the intensifying competition and the volatility of aluminium prices on the world market, it was a matter of pushing further the limits of technologies dating from previous generations.

In relation to the first research objective set out in the introduction, the data show that in our two plants, it was not an “objective” stagnation of productivity that led to the adoption of teamwork. It was rather socially embedded expectations: managers believed that the productivity potential of previous arrangements was drying up, and the existing development of co-operative relations allowed them to put this belief into effect. Teamworking was the next step in a series of endeavours to keep productivity improving.

Part of the explanation for the implementation of teamwork has to do with our second research question regarding idiosyncratic competencies. In both plants, located in very different institutional and cultural backgrounds, we observed and had various forms of interviews with long serving workforces that shared several key features. The local tradition of these aluminium workers from the North of England relates mostly to the mining industry, while those working at the Isle-Maligne smelter grew up in the region where Alcan developed its basis in primary production before expanding worldwide. Clear features of these two cultures are a productive ethos that fosters commitment to work and to efficiency, as well as a robust independence from management, reflected in and supported by their local union. In other words, these workers easily see the rich possibilities of more autonomous forms of work organization, both for their own freedom and for efficiency, but this is quite compatible with a traditional “them and us” vision of employment under capitalism (see also Bélanger 2001). These principles, which were also at work in various historical forms of crew systems and group work, and which are also fostered by continuous process technology, are compatible with modern forms of teamwork.

Among the other conditions underpinning the development of teamwork, we have also highlighted the workers’ relative job security, and the fact that the technical organization of production encouraged continual efforts to improve plant utilization. This analysis takes forward the analysis of Granovetter and Tilly (1988) by showing the specific social arrangements that developed within the facilitating conditions of technology and product markets. Decision-makers in both plants knew that they had to be seen to modernize: Isle-Maligne because of its dated technology; Lynemouth because of its isolated position within the firm and also the fact that its energy costs were high because it used expensive coal as its fuel. Although the plants were not performing badly, it was important that plant managers demonstrated that they were being innovative and forward-looking.

In short, we have developed the idea of idiosyncratic competencies by deploying an analytical approach that gives proper consideration to both the political economy of aluminium production and the study of workplace relations. This stresses the importance of context, of both time and place. For example, the 1970s at Isle-Maligne were not a time when workplace innovation was likely to succeed. By “place” we mean the complex of extant social relations. Such an approach helps us to understand why innovations work in one context and not another. For example, Kleiner, Leonard and Pilarski (2002) show that a teamwork experiment in their plant had minimal effects on productivity, which they attribute to its top-down implementation and lack of consistency with existing relationships. To build on idiosyncratic competencies means paying close attention to the existing skills and expectations of workers, not importing innovations from outside.

This approach has profound practical implications. Teamwork was in historical line with the productive ethos developed in previous decades. In such cases, no revolutionary organizational change and no particular management fad are necessary to evolve toward a collective form of work organization. But it is also essential that managers should pay close attention to the tacit skills held by workers and think about organizational changes that are in line with, and not in contrast to, the structure of social relations. A long tradition of workplace studies identifies tacit skills but also the fact that conditions are rarely in place for workers to wish to deploy them in partnership with management (e.g. Halle 1984). It is now commonplace to observe that workplace innovation remains rare and that many experiments fail. The solution lies in paying much more attention to existing social relations: a managerial style that is less glamorous than the latest change management programme and that calls for humility, respect for existing relationships, and the careful building of trust.

Parties annexes

Note

-

[1]

From smelters with state-of-the-art process technology, the expectations of corporate management as regards output and profitability are much higher. The productivity of such modern smelters, which are in the early phases of capital depreciation, as for instance the Laterrière plant, is hardly comparable to those under study here. Besides limitations as regards research methodology, this is certainly a limitation to the possibilities of internal benchmarking within the corporation, at least as regards productivity.

References

- Appelbaum, Eileen, Thomas Bailey, Peter Berg and Arne L. Kalleberg. 2000. Manufacturing Advantage. Ithaca: Cornell University Press.

- Becker, Brian E., and Barry Gerhart. 1996. “The Impact of HRM on Organizational Performance: Progress and Prospects.” Academy of Management Journal, Vol. 39, 779–801.

- Becker, Brian E., Mark A. Huselid, Peter S. Pickus and Michael F. Spratt. 1997. “HR as a Source of Shareholder Value: Research and Recommendations.” Human Resource Management, Vol. 36, 39–47.

- Bélanger, Jacques. 1999. “Alcan: Market Pressure and Decentralization of Labour Regulation.” Contract and Commitment. Anil Verma and Richard P. Chaykowski, eds. Kingston, Ont.: IRC Press, 113–136.

- Bélanger, Jacques. 2001. “Autorégulation du travail et division sociale: observation dans une aluminerie québécoise.” Sociologie du travail, Vol. 43, 159–177.

- Bélanger, Jacques, and Martin Dumas. 1998. “Teamwork and Internal Labour Markets: A Study of a Canadian Aluminium Smelter.” Economic and Industrial Democracy, Vol. 19, No. 3, 417–442.

- Beynon, Huw. 1973. Working for Ford. Harmondsworth: Penguin.

- Cappelli, Peter et al. 1997. Change at Work. New York: Oxford University Press.

- Clark, Kim B. 1981. “The Impact of Unionization on Productivity: a Case Study.” Industrial and Labor Relations Review, Vol. 33, 451–469.

- Crouch, Colin, and Wolfgang Streeck. 1997. “Introduction.” Political Economy of Modern Capitalism. Colin Crouch and Wolfgang Streeck, eds. London: Sage, 1–18.

- Cully, Mark et al. 1999. Britain at Work. London: Routledge.

- Edwards, P. K., and Hugh Scullion. 1982. The Social Organization of Industrial Conflict. Oxford: Blackwell.

- Elbaum, Bernard, and William Lazonick, eds. 1986. The Decline of the British Economy. Clarendon: Oxford.

- Elger, Tony. 1990. “Technical Innovation and Work Reorganization in British Manufacturing in the 1980s.” Work, Employment and Society, additional special issue, May, 4, 67–102.

- Freeman, Richard B., and James L. Medoff. 1984. What Do Unions Do? New York: Basic Books.

- Geary, John F., and Anthony Dobbins. 2001. “Teamworking: A New Dynamic in the Pursuit of Management Control.” Human Resource Management Journal, Vol. 11, No. 1, 3–23.

- Godard, John, and John T. Delaney. 2000. “Reflections on the High Performance Paradigm’s Implications for IR as a Field.” Industrial and Labor Relations Review, Vol. 53, No. 3, 482–502.

- Graham, Laurie. 1995. On the Line at Subaru-Isuzu. Ithaca: ILR Press.

- Granovetter, Mark, and Charles Tilly. 1988. “Inequality and Labor Processes.” Handbook of Sociology. Neil J. Smelser and Richard Swedberg, eds. Newbury Park: Sage, 205–235.

- Halle, David. 1984. America’s Working Man. Chicago: University of Chicago Press.

- Hill, Stephen. 1974. “Norms, Groups and Power.” British Journal of Industrial Relations, Vol. 12, 213–235.

- Ichniowski, Casey, et al. 1996. “What Works at Work?” Industrial Relations, Vol. 35, No. 3, 299–333.

- Ichniowski, Casey, Kathryn Shaw and Ginvanna Prennushi. 1997. “The Effects of Human Resource Management Practices on Productivity.” American Economic Review, Vol. 87, No. 3, 291–313.

- Juravich, Tom. 1985. Chaos on the Shopfloor. Philadelphia: Temple University Press.

- Kleiner, Morris M., Jonathan S. Leonard and Adam M. Pilarski. 2002. “How Industrial Relations Affect Plant Performance: The Case of Commercial Aircraft Manufacturing.” Industrial and Labor Relations Review, Vol. 55, 195–218.

- Lapointe, Paul-André. 1992. “Modèles de travail et démocratisation: le cas des usines de l’Alcan au Saguenay.” Cahiers de recherche sociologique, 18/19, 155–183.

- Lavallée, Gilles. 1993. “La franchise et l’ouverture: une recette de succès de la négociation.” La négotiation collective du travail, Actes du 48e Congrès des relations industrielles. Québec: Presses de l’Université Laval, 151–157.

- Lazonick, William H. 1979. “Industrial Relations and Technical Change.” Cambridge Journal of Economics, Vol. 3, 231–262.

- Musgrave, Peter. 1986. “British Alcan Lynemouth Limited.” Mimeo, London: Industrial Society.

- Murray, Gregor, Jacques Bélanger, Anthony Giles and Paul-André Lapointe, eds. 2002. Work and Employment Relations in the High Performance Workplace. London/New York: Continuum.

- Nappi, Carmine. 1994. L’aluminium. Paris: Économica.

- Nolan, Peter, and Paul Marginson. 1990. “Skating on Thin Ice: David Metcalf on Trade Unions and Productivity.” British Journal of Industrial Relations, Vol. 28, 227–247.

- Pil, Frits K. and John Paul MacDuffie. 1996. “The Adoption of High-involvement Work Practices.” Industrial Relations, Vol. 35, 423–455.

- Purcell, John 1999. “Best Practice and Best Fit: Chimera or Cul-de-sac?” Human Resource Management Journal, Vol. 9, No. 3, 26–41.

- Ramsay, Harvie, Dora Scholarios and Bill Harley. 2000. “Employees and High-performance Work Systems.” British Journal of Industrial Relations, Vol. 38, 501–532.

- Seashore, Stanley E. 1954. Group Cohesiveness in the Industrial Work Group. Ann Arbor: Survey Research Center, University of Michigan.

- Sisson, Keith, ed. 1997. Towards New Forms of Work Organisation: Can Europe Realise its Innovative Potential? Luxembourg: European Foundation/Office for the Official Publications of the European Communities.

- Wright, Martyn, and Paul Edwards. 1998. “Does Teamworking Work, and if so, Why? A Case Study in the Aluminium Industry.” Economic and Industrial Democracy, Vol. 19, No. 1, 59–90.

Liste des figures

Figure 1

Man Hours per Metric Tonne

Figure 2

Net Kg aluminium per Pot per Day

Liste des tableaux

Table 1

Mean Annual Change in Man Hours per Metric Tonne (MHMT)

Table 2

Mean Hours Spent on Training

10.7202/1002307ar

10.7202/1002307ar