Résumés

Abstract

The automotive industry has long been a leader in the introduction of new forms of work organization and technology—including mass production and high performance work systems (HPWS). It has also been a focal point for how trade unions negotiate such systems. Recently, much attention has focused on Industry 4.0 (I 4.0)—a manufacturing system featuring advanced robotics, digitalization and artificial intelligence. However, in the automotive industry, I 4.0 is confronted with considerable technical and social challenges, and I 4.0 paradigms have been criticized for marginalizing the continuing importance of employees in shaping, if not ‘hybridizing,’ such new production processes.

Based on a study of UNIFOR union locals in Canadian automotive assembly plants, we argue that I 4.0 has to be analyzed in terms of the ways unions have influenced the almost universal adoption of HPWS in that sector. We thus investigate the ways unions have impacted HPWS and its implications for their roles in workplace integration of I 4.0. As such, we first argue that, while overlapping, HPWS and I 4.0 represent different managerial strategies. Second, we develop an exploratory analytical framework for use in examining union roles in negotiating HPWS and technology adoption.

Based on this framework, we then analyze 18 interviews we conducted in 2017-2018 with plant managers and key UNIFOR representatives at five southern Ontario assembly plants. The interviews illustrate not only commonalities in adoption of HPWS, but also differing ways in which the union influences the ‘hybridization’ of HPWS. Union practices differ significantly from one plant to another as a function of three variables: 1- firm-plant competitive positions; 2- the union’s overall monopoly face; and 3- internal union local solidarity and narratives around HPWS. Keeping these commonalities and differences in mind, we then consider the challenges that unions are likely to confront as they begin negotiating I 4.0.

Keywords:

- automotive industry,

- trade unions,

- high performance work systems,

- industry 4.0

Résumé

L’industrie automobile est, depuis longtemps, un chef de file dans l’introduction de nouvelles formes d’organisation du travail et de technologie, y compris la production de masse et les modèles de gestion à haute performance (MGHP, High Perfomance Work Systems-HPWS en anglais). Il a également été un point focal quant à la manière dont les syndicats négocient de tels systèmes. Récemment, une grande attention s’est portée sur l’Industrie 4.0 (I 4.0), un système de fabrication doté de la robotique avancée, du numérique et de l’intelligence artificielle. Cependant, dans l’industrie automobile, l’I 4.0 est confronté à des défis techniques et sociaux considérables. De plus, les paradigmes I 4.0 ont été critiqués pour avoir marginalisé l’importance continue des employés dans la conception, sinon ‘l’hybridation’, de ces nouveaux processus de production.

En nous fondant sur une étude des sections locales des syndicats d’UNIFOR dans les usines d’assemblage de véhicules automobiles au Canada, nous soutenons que l’I 4.0 doit être analysé en fonction de la manière dont les syndicats ont influencé l’adoption presque universelle des MGHP dans ce secteur. Nous examinons donc les effets des syndicats sur les MGHP et les implications de leur rôle dans l’intégration de l’I 4.0 sur le lieu de travail. En tant que tels, nous soutenons d’abord que, bien qu’ils se chevauchent, les MGHP et l’I 4.0 représentent des stratégies managériales différentes. Deuxièmement, nous développons un cadre d’analyse exploratoire à utiliser afin d’examiner les rôles des syndicats dans la négociation des MGHP et l’adoption de la technologie numérique.

Grâce à ce cadre d’analyse, nous analysons ensuite 18 entrevues que nous avons menées en 2017-2018 avec des directeurs d’usine et des représentants-clés d’UNIFOR dans cinq usines d’assemblage du sud de l’Ontario. Les entretiens illustrent, non seulement les points communs dans l’adoption des MGHP, mais aussi les différentes manières dont le syndicat influence ‘l’hybridation’ des MGHP. Les pratiques syndicales diffèrent significativement d’une usine à l’autre en fonction de trois variables: 1- la position concurrentielle entreprise-usine; 2- le visage global du monopole syndical; et 3- la solidarité et les récits internes du syndicat local autour de MGHP. En gardant à l’esprit ces points communs et ces différences, nous examinons, ensuite, les défis auxquels les syndicats sont susceptibles de faire face lorsqu’ils entament les négociations I 4.0.

Mots-clés:

- industrie automobile,

- syndicats,

- modèle de gestion à haute performance (MGHP ou HPWS),

- industrie 4.0

Corps de l’article

Introduction

The automotive industry has long been a leader in the introduction of new forms of work organization and technology—including mass production and high performance work systems (HPWS) (Womack et al., 1990). Not surprisingly, it has also been a focal point for how trade unions negotiate such systems (Rhinehart et al., 1997; Wenten, 2017). Recently, much attention has focused on Industry 4.0 (henceforth “I 4.0”)—a manufacturing system that features advanced robotics, digitalization and artificial intelligence (Helper et al., 2017; Yates and Holmes, 2019). However, in the automotive industry I 4.0 is confronted with considerable technical and social challenges that make it difficult to scale up (Rainnie and Dean, 2020). Furthermore, I 4.0 paradigms have been criticized for marginalizing the continuing importance of employees in shaping, if not ‘hybridizing,’ such new production processes (Kopp et al., 2016; Helper et al., 2017).

Based on a study of UNIFOR trade union locals at Canadian automotive assembly plants, we argue that I 4.0 has to be analyzed in terms of the ways unions have influenced the almost universal adoption of HPWS in that sector.[1] In this exploratory article, we thus investigate the ways unions have impacted HPWS and the implications this has for their roles in workplace integration of I 4.0. To better understand union roles in negotiating HPWS and I 4.0 we first distinguish between HPWS and I 4.0, arguing that, while overlapping, they also represent different managerial production strategies. Second, after critical examination of the literature, we develop an exploratory analytical framework for use in examining union roles in negotiating HPWS and technology adoption. By means of this framework, we then analyze 18 interviews we conducted in 2017-2018 with plant managers and key UNIFOR representatives at five southern Ontario assembly plants. We find that I 4.0 adoption is in its initial stages and is embedded within HPWS. The interviews illustrate not only commonalities in adoption of HPWS but, also, differences in the ways the union influences ‘hybridization’ of HPWS. Union practices differ significantly from one plant to another as a function of three variables: 1- firm-plant competitive positions; 2- the union’s overall monopoly face; and 3- internal union local solidarity and narratives around HPWS. Keeping these commonalities and differences in mind, we then consider the challenges that unions are likely to confront as they begin negotiating I 4.0.

High Performance Work Systems, Industry 4.0, and Union Involvement in Automotive Assembly

For over a century, the automotive industry has been in the vanguard of automation and new forms of work organization. For many observers I 4.0 is no exception (Kopp et al., 2016; Groshen et al., 2018). I 4.0 features shorter production runs of mass-customized goods using ‘intelligent’ robotics, artificial intelligence (AI), and pervasive digitalization of production and exchange between producers and customers (Totterdill, 2017). As such, I 4.0 is principally a technological solution to the problems of monitoring and co-ordinating processes within the overall production and consumption chain. It, thus, differs from earlier phases of automation, such as transfer machines and robots, which were not digitally interconnected.

In contrast, HPWS which has been developing since the late 1980s, can involve both ‘hard’ technologies, such as computer-aided design and manufacturing (CAD-CAM), and ‘soft’ ones, such as quality analysis and benchmarking, but is mainly a form of work reorganization to improve production processes through flatter managerial hierarchies, greater employee and team autonomy in work design and performance, task rotation, and multiskilling (Aghazadeh and Seyedian, 2004; Lippert et al., 2014).

There are, however, some critical intersections and synergies between HPWS and I 4.0. First, I 4.0 in the automotive industry is being introduced in a context of almost universal adoption of HPWS. Second, by contributing to production process improvement HPWS can act as a precursor to advanced I 4.0 automation, which in some cases can also build upon the emphasis in HPWS on greater decentralization and employee participation for its deployment (Helper et al., 2017).

Some observers argue that HPWS and automation have increased standardization and are ‘commodifying’ automotive production processes across different locations (Mordue and Sweeney, 2017: 183). However, countries and manufacturers differ significantly in the ways they have influenced HPWS and are shaping I 4.0 adoption (Lippert et al., 2014; Lloyd and Payne, 2019). For instance, I 4.0 is more technology-centred, less stakeholder-inclusive, and less socially inclusive in the U.S. than in Germany (Rainnie and Dean, 2020).

Furthermore, there is skepticism over claims that I 4.0 will radically reduce labour requirements (Rainnie and Dean, 2020). For instance, previous waves of technological innovation have failed to meet expectations that automotive final assembly would be completely automated (Kopp et al., 2016). In fact, some automotive manufacturers, such as Mercedes Benz, have become less reliant on automation in final assembly and more so on labour (Gibbs, 2016). Finally, labour requirements can be reduced more through HPWS work intensification via reorganization of processes than through I 4.0 technology (Moody, 2018). I 4.0 must be seen as one part of this reorganization of processes, and it is this reorganization that unions and workers might have power to influence.

As such, regardless of how management views them, new production systems are always inextricably bound up with the employment relationship (Grimshaw and Rubery, 2005). Some scholars, in fact, argue that I 4.0 will not reach its full potential without a capital and labour partnership that “moves away from its traditional focus on industrial relations” to become an “important driver of, and resource for organisational innovation in the broadest sense” (Totterdill, 2017: 72). I 4.0 may both help and harm workers in an optimistic, ‘specialization’ scenario that involves major upskilling of workers and elimination of more physically demanding and dangerous work (Avogara, 2017). This is in contrast to a more pessimistic ‘automation’ scenario wherein new technologies replace and control even highly-skilled workers, while intensifying work and eroding work-life balance. Importantly, while unions are often involved relatively late in the process of technology adoption, this may not be the case with I 4.0, which is at a new, if not experimental, stage. Some thus argue that unions have a key opportunity to “shape innovation in ways supporting fair and affordable working conditions, and to strengthen their …. [union] capacity for autonomous action and decentralised self-regulation [because] based on past experiences with automation, the degree of process stability produced under laboratory conditions is hardly achieved in practice” (Krzywdzinski et al., 2016: 22-23).

In North America, I 4.0 is also viewed as an opportunity for enhanced labour-management co-operation (Groshen et al., 2018). However, unlike many European coordinated economies, American and Canadian workers generally lack formal rights to workplace representation, and consultations are generally limited to renewal of four-year contracts (Lippert et al., 2014). American and Canadian laws and collective agreements do give unions some rights to advance notice of technological change that affects employment, but businesses have long resisted co-management arrangements, thus contributing to a significant “influence gap,” i.e., employees have less influence than employers over job design (Knight and McPhillips, 1989; Kochan et al., 2018; Livingston and Raykov, 2008). Indeed, some in Canada’s private sector view the adoption of I 4.0 technologies as simply a means to keep labour costs down and see no other role for unions in the process (Tanguay, 2018).

Given this context, both the United Auto Workers-UAW (2019) and UNIFOR (2018) argue that workers can secure maximum influence over I 4.0 through collective bargaining agreements. The UAW has, thus, negotiated with GM to have skilled trade workers run 3D printing rooms as part of ‘worker enhancing’ strategies, and the 2019 UAW-GM contract established a joint National Committee on Advanced Technology to meet quarterly and discuss how GM plans to implement new technologies, including electric vehicles (Helper et al., 2017; McEachern, 2019).

We would also argue that union I 4.0 interventions occur in a workplace that has been already shaped by HPWS adoption (Lippert et al., 2014). What, then, are the implications of union negotiation and its ‘hybridizing’ of HPWS (Wenten, 2017) for workplace integration of I 4.0? Longstanding research on HPWS and unions has provided critical insights into how unions are impacted by and negotiate HPWS. Such research underscores two opposing outcomes. The first outcome is a largely complimentary union-HPWS relationship resulting in mutual gains by workers, by their unions, and by businesses—especially when supported by union-firm partnerships (see Appelbaum et al., 2000; Kristensen and Rocha, 2012). A strong but co-operative union presence actually facilitates successful implementation of HPWS (Pohler and Luchak, 2015).

In contrast, another body of research points to a different outcome: HPWS can challenge if not undermine unions (Wells, 1993; Danford et al., 2009; Osterman, 2018). HPWS managerial techniques can weaken union capacities by causing workers to question solidarity and collective identity (Waddington, 2015). Thus, union-HPWS partnership strategies may not only have little impact on worker job satisfaction but, also, lead to more negative evaluations of union performance (Danford et al., 2009). A more adversarial approach may secure greater managerial concessions to union concerns (Bacon and Blyton, 2006).

Researchers attribute such differences in the impact of HPWS on unions to a range of contributory factors, including national or institutional effects. For example, in Coordinated Market Economies (CMEs), employment relations institutions may provide employees with more statutory rights to have a say in the way the business is run and more employment protections, thus promoting greater union-firm co-operation on HPWS than in Liberal Market Economies (LMEs) (Liu et al., 2009; Lippert et al., 2014). However, national economies are increasingly integrated into the global production networks (GPNs) of multinational enterprises (MNEs). Thus, firm-specific strategies and plant position in global value chains can also be a significant factor in union negotiation on HPWS (Lewchuck et al., 2001; Krzywdzinski, 2017).

Though important, the roles of national institutions, MNEs, and GPNs are “mere potentiality, realized only when acted upon by managers and workers” (Wenten, 2017: 203). Some studies have also stressed the active role of unions and their workplace agency over HPWS (Frost, 2001; Bacon and Blyton, 2006). They particularly stress: 1- the union’s ability to leverage a ‘monopoly face’—that is, to use a high union density as a credible threat for strikes and other actions that can block or disrupt managerial workplace initiatives (Pohler and Luchak, 2015); 2- the ability to mobilize internal solidarity and a deliberative vitality via the presence of a strong network of shop-floor representatives and the union’s ability to leverage wider institutional resources (such as employment law); and 3- the union’s power to craft counter-narratives to managerial workplace rationales, thus further promoting shop-floor solidarity (Lévesque and Murray, 2010).

In the following examination of UNIFOR’s negotiation of HPWS, we recognize the overall importance of the institutional context and the role of GPN and firm-specific factors, but we will especially emphasize, as independent variables, how plant or local union representatives: 1- draw upon their monopoly face, 2- mobilize their internal solidarity and deliberative vitality, and 3- mobilize craft narratives in order to negotiate HPWS adoption, which is our dependent variable. This analysis and the following discussion will enable us to understand the ways unions have been impacting HPWS and the implications such ways have for union roles in workplace integration of I 4.0.

Methodology

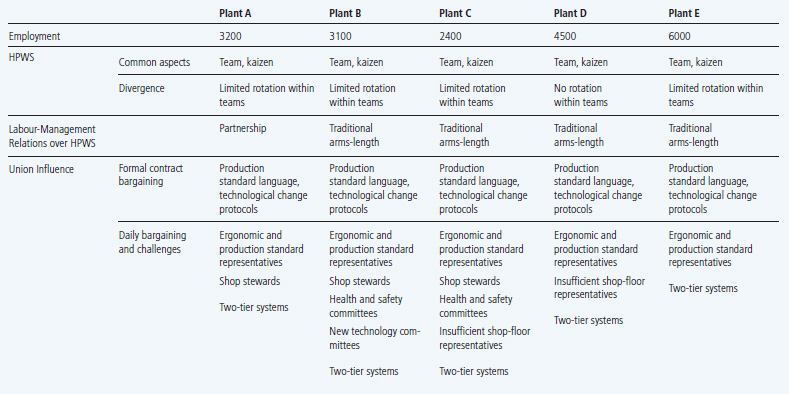

In our study, we rely on an exploratory qualitative methodology. This methodology is especially useful for understanding how key actors perceive how and why complex social interactions, such as work system reorganization, occur (Yin, 2003). In 2017 and 2018, we interviewed 10 union local representatives and eight HR directors or managers at five assembly plants in southern Ontario. The focus was on HPWS deployment and the forces shaping it. In exploring this topic, I 4.0 emerged as a process embedded within HPWS. All plants were large-scale operations with 2,400 to 6,500 employees (see Table 1). At two of the union plants we conducted paired interviews, i.e., separate meetings with managers and union representatives, while at a third the managers and union representatives were interviewed together. Management at two assembly plants refused to grant an interview, although we did meet with union representatives at both. In the interviews, managers were asked about their HPWS strategies and how I 4.0 was being adopted in this context, especially in relation to the UNIFOR union. Union representatives were asked about the impacts of HPWS on their members’ skills and work conditions and about union strategies for negotiating HPWS and new technologies being introduced by I 4.0. All interviews except one were recorded and transcribed. Each researcher then analyzed them independently for passages providing insights into core organizational and technological change, work intensification, and the union’s impact on HPWS and new technologies.

Table 1

Surveyed Plant Characteristics and Union HPWS Bargaining

Canadian automotive manufacturers have been adopting HPWS since the late 1980s (Rhinehart et al., 1997). Our interviews also revealed major investments over the last five years in I 4.0-related technologies, especially digitilization. This area of investment included robots, which had long been utilized but were now being deployed with digitally-linked sensors. Some manufacturers sought not only to use such technologies for systemic integration within plants but, also, to ‘synchronize’ them across plants and other facilities, including those overseas. Managers, thus, had an increased ability to monitor production bottlenecks and to ‘backtrack’ for quality and other production issues within and across plants. I 4.0 is also impacting primarily skilled workers, with some acquiring new competences in 3D printing or developing ‘mechatronic’ skills— mechanical engineering integrated with electronics. Our research also revealed that robotics was mostly concentrated in relatively repetitive operations, e.g., in welding and in engine and suspension system installation. Furthermore, especially at the stage of final assembly, managers considered over-reliance on technology to be a liability because the lack of human dexterity led to lower product quality and more downtime.

These limits on automation meant that many operations were “still physical work” (PLANT C, union, 08/21/2017). Furthermore, interviews revealed that I 4.0 adoption not only is limited but, also, largely reinforces, rather than transforms the forms of HPWS logic that still dominate organization of workplace production and union responses to it. For HPWS, some forces are pushing production sites to adopt certain uniform aspects, while others are fostering a variety of hybrid forms of HPWS. Most interviewees particularly mentioned increased standardization of assembly work, higher work intensity, and focus on continuous cost reduction. Both union and manager interviewees also acknowledged the relatively restricted autonomy for making plant-level changes. One manager stated that HPWS “… is a program, a process. The company owns it. It’s not open for negotiation” (PLANT D, manager, 08/21/2017). Moreover, union representatives felt that the focus of HPWS was to drive down labour costs and eliminate jobs. As one stated, “[the firm] has an objective, every year, to eliminate jobs. And that’s what they do—[about] 10% of the workforce every year.” (PLANT D, union, 07/19/2017).

With HPWS implementation, work intensity has increased across plants with average TAC time (the time given to a line operator to complete the assigned task), being reduced—in most cases—to one minute or less. Increasing work intensity has also meant relatively modest upgrading of production employee skills, including kaizen techniques, quality control, and some minor maintenance tasks that had formerly been exclusively performed by skilled tradespersons.

All of the plants under study had introduced teams into their shop-floor production systems, the teams ranging in size from five to 13 members. Furthermore, most plants rotated team members among different jobs, mostly to reduce repetitive strain injuries. The extent of this rotation varied. At some plants, rotation was limited, in part because “the vision of people rotating through the teams was a little too ambitious for us from a cost perspective because there is a lot of training involved with that and it was never really realized” (PLANT D, Manager, 08/21/2017).

Finally, while we found some evidence confirming Mordue and Sweeney’s (2017) commoditization arguments, our study also revealed uneven adoption of HPWS. This unevenness stemmed from several factors. All firms had adopted some variant of HPWS, but they differed significantly in both the length of time and the aspects of HPWS they had adopted. The differences in part reflected firm- and plant-specific factors, including overall managerial strategy. We will examine those factors below, with emphasis on their interaction with union bargaining.

UNIFOR locals, HPWS, and Technology Adoption

Like the CAW, UNIFOR took a strong national position against HPWS during introduction of such systems in the early 1990s (Rinehart et al., 1997). However, the union was also committed to “a productive workplace producing quality products” and often cooperated on HPWS when plants were threatened with closure (Holmes and Kumar, 1998: 260). Indeed, by the early 2000s unionized Canadian assembly operations ranked amongst the highest in North America for productivity and quality (Charles River Associates, 2001: 112- 119).

Nonetheless, it was clear from the interviews that HPWS adoption is now increasingly on company terms. This change reflects the weakening of both UNIFOR’s position within North American GPNs and its ‘monopoly face’—in particular, UNIFOR’s overall bargaining position and coverage. Especially since the 2008-2009 crisis, automotive assembly investment has increasingly shifted toward the Southeastern U.S. and Mexico. Furthermore, since 2000, three Canadian assembly plants have been closed and over 13,000 jobs lost (Yates and Holmes, 2019). UNIFOR’s monopoly face has also weakened as assembly plant unionization fell from 73% in 2005 to 58% in 2014 and as wages also stagnated (Sweeney and Mordue, 2017).

Some union interviewees insisted that “the union has never been against any operating system” (PLANT A, union, 07/21/17). With increasing pressures to restructure, it has become less important to resist HPWS than to attract and retain product investment, a subject that now accounts for approximately 90% of formal contract bargaining (PLANT D, union, 07/19/2017). Nonetheless, the union still possesses some GPN and monopoly face leverage. Thus, in 2017, UNIFOR staged a well-supported strike at one assembly plant to get it designated as the exclusive lead facility for a strong-selling SUV. The strike did not succeed. When an assembly plant is assigned a particular model within its lifecycle, the union can use product commitment levers to restrict the firm’s ability to move production to other facilities (PLANT B, union, 06/06/2018). Furthermore, because some plants were the last ones remaining of their firm’s Canadian assembly operations, this fact was viewed as giving union locals political bargaining leverage (PLANT D, union, 07/19/2017). Finally, interviewed non-union assemblers felt that UNIFOR was a significantly more ‘credible threat’ than the UAW to employers who feared unionization of their employees.

Their positioning in GPNs and the changes to the union’s monopoly face were not the only factors influencing UNIFOR locals’ bargaining over HPWS. There was also the union’s ability at the assembly plant level; 1- to leverage internal solidarity and its deliberative vitality and, relatedly; 2- to craft counter-narratives to management narratives over workplace change. In terms of its internal solidarity and deliberative vitality UNIFOR has long had a reputation of having a stronger democratic, decentralized, and mutually supportive culture than the UAW has had (Kumar and Holmes, 1998). Since 2000, however, union shop-floor capacities and solidarity have been weakened by a combination of factors: increasingly centralized union decision-making; plant closures; retiring activists; and concessions on two-tier or blended wage and benefit systems for new hires (Siemiatycki, 2012).[2] For example, in at least two plants (PLANTS C and D) the departure of several retiring shop stewards significantly reduced not only union institutional memory but also the ability to enforce collective agreements and bond new hires to the union:

We lost about 22 representatives on the floor… It really put a distance between the membership and the union. In the meantime, we hired approximately 2,000 people…..We found it very, very challenging to build that confidence in the union. It seems we’re fighting a constant battle of, “Do our membership pay more heed to the company or do they pay more heed towards what the union tells them?”

PLANT D, union, 07/19/2017

Such issues could reduce the union’s deliberative vitality. Furthermore, while formal union meetings could be well attended, and while all locals had Facebook and Twitter accounts, social media could be used by disgruntled members to make what were viewed as unfounded complaints against union leadership (PLANTS D + B). Finally, team systems themselves could be a source of division too, especially if team leaders considered themselves more aligned with management than with the rank-and-file and the union.

Yet, strong countertrends were also helping promote greater solidarity within the union. First, especially in the Greater Toronto Area (GTA), some plant workforces were becoming more diverse, and union locals had established equity group committees for gender, sexual orientation, and race, this move being viewed as increasing the union’s deliberative capacity. Similarly, in some locals the decline in activism had been reversed—especially on the issue of two-tier employment systems. In one case, workers with seniority joined with new hires to reject a national union’s negotiated contract; in another, a recent strike had made the “membership a lot stronger—a lot more union than we’ve ever had” (PLANT B, union, 06/05/2018). Furthermore, internal solidarity had increased in some circumstances through struggles against HPWS work intensification (PLANT C, union, 08/25/2017).

These trends were also evident in local union capacity to craft counter-narratives to management narratives. This was critical since several union interviewees agreed that most firms had become better at both providing rationales for HPWS and listening to union and rank-and-file concerns (PLANT C, union, 08/25/2017). One manager stated, “HPWS has provided a common narrative on the shop floor. We need to have an engagement with everyone including line operators to produce problem solving.” (Corporate Production Manager, 09/20/18). Furthermore, firms deployed a customer-focused discourse, which could also ‘draw in’ union local leaders. As one union member stated: “I think we (the firm and the workforce) all have the same goal …and that’s to say, ‘The customer is our main goal. To satisfy the needs of the customer is what we always try to do.’” (PLANT D, union, 07/19/2017). Yet, as we will explore below, unions also did develop strong HPWS counter-narratives—especially on health and safety. Finally, while strong firm narratives could entice union locals into more formal HPWS partnerships, with the exception of one local examined below, most expressed skepticism over such arrangements: “At the end of the day, the firm will make the decision. We have our input but in a partnership it would be where we have a lot more say that’s accepted, right?” (PLANT C, union, 08/25/17).

UNIFOR locals influenced the union’s negotiation of workplace and technological change through their ability to promote solidarity and sustain deliberative vitality and counter-narratives. However, the union’s HPWS strategy had changed considerably: “With the CAW, the union resisted lean in the 1990s. The problem was in the 1990s, lean was not clearly defined … Now, we have gotten smarter and forced the firm to define HPWS” (PLANT A, union, 07/21/2017).

This process of defining HPWS by UNIFOR was important. By negotiating some controls over production standards and ergonomics, UNIFOR created a source of variation not only in HPWS but, also, in how new technology was introduced. Thus, union representatives welcomed new technology that was better designed ergonomically so that workers did not have to bend or kneel in awkward positions. Managers emphasized how I 4.0 digital technologies, combined with HPWS, allowed constant monitoring of product manufacturability (Corporate Production Manager, 09/20/2018). For union representatives this change meant HPWS had more ‘measurables,’ further increasing employee stress (PLANT B, union, 06/06/2018). For both HPWS and any new technologies associated with it, UNIFOR made employee concerns known; 1- during formal contract negotiations and model changes; and 2- during daily shop floor informal bargaining.

Formal Contract and Model Change Bargaining

Formal contract negotiations were an especially important opportunity for the union to influence work organization if there were to be model changes over the life of the agreement (usually four years). Furthermore, while collective bargaining was mostly focused on product and related technology changes, it also included ergonomics and production standards. Production standard language regulated how time studies of operative work capacity and fatigue were to be conducted (PLANT D, 2016 Collective Agreement). When bargaining over these topics, unions forced firms to make additional labour available when model mix or other changes occurred, and both parties decided how disputes over such standards were to be resolved. Furthermore, all plants had production standard and ergonomic representatives (usually two each per plant) who had the right to challenge managers (for example, by retiming jobs) in order to address ‘over-cycled’ jobs.

There was another point on which the union would intervene during workplace integration of more recent technologies, some of which were I 4.0-related. The union had bargained for advance notice (up to a year) for new technologies likely to lead to job loss. This gain also involved the redesign and retiming of jobs, and allowed the union some scope for negotiation (PLANT D, manager, 08/21/2017). One union representative commented:

It is supposed to be a year, but they really can not cut jobs. They have to find us other work unless it is a brand new product, then they have absolutely every right. … They brought automatic stackers into stamping and we used to have four people stack. We can not stop them, but those four people have to have a job somewhere in the plant.

PLANT B, union, 06/06/2018

Daily shop-floor informal bargaining

In most cases, the union would deal with organizational and technological changes on a more daily, informal, and incremental basis. For example, managers acknowledged that HPWS was subject to incremental modifications in terms of how it was implemented: “I think that dialogue occurs in the plant. … you know there’s a vision of HPWS, a vision in terms of rules and responsibilities of work-group leaders for example. And they have suggestions about … maybe we could do it this way, right?” (PLANT D, manager 08/21/2017).

Another significant forum of union influence involved provincially mandated health and safety committees:

It is more informal. So when we’re talking, our safety committees…We look at, over the last three years, what issues have come up, and we try to address them at bargaining. So, on the joint health and safety committee, let’s say, or the worker safety committee, we may be discussing the downfalls that we see with job rotation and how we could improve it.

PLANT C, union, 08/21/2017

An important part of day-to-day bargaining was the role of shop-floor production standard and ergonomic representatives, whose importance at most plants had increased significantly under HPWS. In one plant, union interviewees noted there could be significant discrepancies between how the firm described specific jobs and their actual physical requirements—especially when technology and operators were moved to other spaces on the shop floor. Such discrepancies led to disputes between managers and production standard representatives over who would analyze, re-time and negotiate new standards (PLANT C, union, 08/21/2017). In another plant, a union interviewee stated, “Now, the ergonomist and safety time standard (representative) have to sign off. It does delay it by a couple days, which gives us time for input…The speed is now locked. They can not change the line speed ever. That’s in our contract” (PLANT B, union, 06/06/2018).

However, when the work is brought into line with ergonomic and overall production standards, the result is more strain on shop-floor representatives, including stewards. At several plants, these representatives were often considered ‘too busy’ to assist employees over ergonomic, over-cycling, and contract-related issues. At PLANT H, the union noted that they only had one production standard representative per shift and not six industrial engineers, as required by the firm’s monitoring standards. At two facilities, the increasing workload also made it harder to recruit stewards (PLANTs C and D).

We can best understand how locals can leverage their internal solidarity and counter-narratives to negotiate workplace change by comparing two assembly plants owned by the same firm. The firm had introduced its HPWS into its Canadian operations in 2008, giving employee safety the highest priority in the system’s technical and managerial ‘pillars.’ The system also provided for greater operator involvement and some limited decision-making over work organization and technology utilization. This HPWS also helped support the more decentralized decision-making required by 1 4.0 technologies (Corporate production manager, 09/20/2018).

The two plants differed in their size (PLANT A had 3,200 and PLANT E 6,000 employees) and in their place in firm production strategy. PLANT E was effectively a ‘flagship’ producing high-value vehicles. It had over 1,200 robots and, since 2015, had received over $2.6 billion in investment—some of it I 4.0-related, as part of a retooling to produce electric vehicles. It also had the best HPWS rating of any of the firm’s North American operations. In contrast, PLANT A produced lower-value passenger vehicles and had a lower HPWS rating. It had fewer than 600 robots and since 2015 received only $325 million in investment. Indeed, plant managers admitted that the plant was using old technologies, and one of the main challenges was keeping it operational.

Yet, even at PLANT E, most new investment was not I 4.0-related but rather in the form of more ergonomically-friendly skillet lines. Moreover, at both plants the technologies, such as robotics, were largely subject to the HPWS logic of shorter TAC times. As a PLANT A manager argued, “We have been able to reduce it [TAC] because [of] a lot of the body shop being robotics and everything else. What they have done with HPWS is we did video analysis in order to look for opportunity with the motion of the robots in order to find cells [that] wouldn’t be able to achieve cycle time.” (PLANT A, 07/28/2017).

Most importantly, the workplace was changed within the bounds of union-management plant relations. Here, the firm’s HPWS narrative was critical because managers needed union cooperation as a source of process innovation. Thus, managers argued it was through “joint discussion [that] ….the union has been trained to talk the same language” (Corporate manager, 09/20/2018). The workforce was also viewed as important for identifying anomalies and doing minor maintenance of machinery, including I 4.0 technology. Such worker input was principally driven by cost factors: “We look at cost deployment. That is a compass for finances of the plant. That drives you to prioritize where you are going to take your time because everybody’s busy. So you want to use that time to get the best savings back” (PLANT A, manager, 07/28/2017).

Because UNIFOR would negotiate a master agreement for both plants, there were many similarities in union local strategies, including their counter-narrative to the management narrative. Union locals had accepted the HPWS system, but for the union this acceptance meant that the firm also had obligations:

We bought into the program, so to get our buy in, we have got to get our members to buy in. If our members see them abusing the program it looks like we bought into that. We take the stance, “This is your program. These are your rules. Follow your rules, and we can find a resolution, but if you’re not going to follow your own rules, it’s hard to find a resolution.

PLANT E, union, 06/27/2018

At both plants, the union’s view was that the reality of HPWS was quite divergent from the firm’s narrative. Union interviewees liked aspects of the new HPWS, such as better ergonomics, but argued that, in practice, it contradicted management goals of giving priority to worker safety. Thus, PLANT A union respondents argued that their counter-narrative was “to hold [the firm] accountable to their own process, because they [the firm] just cherry-pick” (PLANT A, union, 07/21/2017). The continuing prioritization of production output led to jobs being ‘over-cycled’ as the firm added more tasks and as operators’ rest time was cut back. This intensification led to more repetitive strain injuries, which HPWS was supposed to minimize:

If something goes wrong, management just keeps saying: “Keep things moving.” The priority is really just maximizing production. One problem is that while the employee is supposed to be at the top of the work system, and we are encouraged to submit suggestions to improve work, things are not being done.

PLANT E, union, 07/21/2017

Union locals dealt with this problem by adopting different strategies. The PLANT A union adopted a de facto partnership strategy that even included management representatives participating in union meetings. Union representatives were well aware of the unorthodox nature of this strategy but argued that the partnership would help the plant achieve higher ratings and secure more investment. Other interviewed local members, however, indicated there were tensions and said that this partnership, which also included the union performing some human resource management tasks, might be ‘blurring’ union-management roles.

In contrast, the PLANT E union had a more traditional arms-length relationship with the firm. It had a stronger GPN position, with a long history of activism and plant and community solidarity to draw upon, while several local leaders had become national union presidents. Both plants had a significant proportion of lower tier workers, and this fact was a challenge to internal solidarity, but the PLANT E local was able to adopt a more independent position vis-à-vis HPWS. Thus, they made the management sign a charter requiring the firm to secure formal agreement from the union first before any HPWS changes were made:

If they roll something new or a new level of HPWS it goes through us. We look at it, we come up with a resolution on how it is going to be rolled out, and then we roll forward. [Our manager] knows that to move ahead we have got to be a part of it. He respects us and if we say “No” and we are strong at “No”, then he knows he’s got to find another avenue.

PLANT E, union, 06/27/2018

Like other surveyed plants, both PLANT A and PLANT E had new technology committees and had negotiated technological change notification. Adoption of advanced technology mainly impact skilled trades persons, rather than semi-skilled workers, for whom HPWS was still the most important factor. Nonetheless, the union locals differed significantly in how their strategies were deployed, “If you look at [the firm’s two plants], there are distinct differences. We run the same program, but there are distinct differences in how we implement them. They run more straight to the book… We localize our agreement a bit.” (PLANT E, union, 06/27/2018).

Such differences were partly attributed to PLANT A having gone through several recent plant manager changes, while PLANT E had the same manager for nearly a decade with a strong working relationship with the union. This and the above factors meant that the PLANT E union drew a sharper line between skilled and semiskilled tasks and was able to force the firm to train operatives when jobs were being restructured. PLANT E production standard representatives were also very assertive in negotiating organizational and technological change:

They [production standard representatives] give it to the shop steward and the committee person, [and] review it… I think they do it five days before any move. So it gives us five days to go through it and challenge things, bring it to our experts, and say: “Look through it and see if it’s right.” And they will do that and say: “This is OK” or “This might be a change we could make.” When the change is made, generally, they go a lot smoother.

PLANT E, union, 06/27/2018

Divergences between PLANT A and PLANT E should not be exaggerated. Besides being under the same master contract, union representatives also continually exchanged information and best practices. Yet there were some differences due to local union solidarity, strategy, and practice, and these differences contributed to the PLANT E union having greater leverage in negotiating HPWS and technological change. In both cases, however, while the union could not stop workplace changes, they could negotiate the introduction of such changes in ways that contributed to greater hybridization.

Discussion

In this paper, we have investigated the UNIFOR union’s negotiation and hybridizing of HPWS and its implications for workplace integration of I 4.0. Our research reveals that Canadian automotive assemblers initially implemented I 4.0 technologies largely within an HPWS logic of lowering costs. Furthermore, HPWS has shaped UNIFOR workplace strategies that are driven by the need to secure and retain investment. The national and GPN context of the plant and firm-specific factors did influence union strategies. Here, we also emphasize the union’s ability in the workplace to craft counter-narratives and especially the ability of shop-floor production standard and ergonomic representatives to impact and hybridize HPWS (Figure 1). Furthermore, as suggested by other Canadian studies, managers often recognized the union’s positive role in process innovation (Walworth, 2010). However, union responses were mostly reactive and occurred late in the process of adopting new forms of organization and technology. Furthermore, with the advent of two-tier employment systems and the decline of shop-floor union representation at some plants, the union may be further weakened in its ability to protect worker interests, including those related to health and safety.

Figure 1

Union and HPWS Workplace Integration of Industry 4.0

Our study has several implications. First, it underscores the importance of shop-floor representatives. A strategic goal of UNIFOR (2018: 17) for I 4.0 is “keeping workers at the centre of decision-making when it comes to technological change in the workplace.” As noted above, UNIFOR representatives are mostly reactive to new technology. European studies of I 4.0 also show the increasing demands it is making on workplace representatives, and some North American studies favour adopting German-style co-determination and works councils for more worker empowerment (Gaddi et al., 2017; Bosch and Schmitz-Kiebler, 2020; Groshen et al., 2018). Although German works councils are now negotiating earlier involvement in I 4.0, they do not have greater formal powers than do North American unions when it comes to obtaining advance notice or having a say in technology (Kochan et al., 2018). Furthermore, whenever German unions have launched I 4.0 initiatives, not only do they face resistance from firms but the works council representatives also lack the necessary expertise to bargain over such technologies (Bosch and Schmitz-Kiebler, 2020). Thus, not only will unions have to negotiate the earliest possible co-involvement in I 4.0 but local and shop-floor representatives will also require significant technical training and support.

Relatedly, when HPWS was introduced, UNIFOR was the only North American union to establish a Department of Work Organization, which provided support and a counter-narrative for its locals (Gindin, 1995). For unions to have meaningful influence over I 4.0, they will require much greater national organization and investment in technological and other expertise, which could come at the expense of other union priorities, including organizing (Bosch and Schmitz-Kiebler, 2020). Unions will thus need to decide how much they should focus on I 4.0, especially since union-firm co-determination of technology has not been a traditional focal point of union strategies.

Another question remains. In what way should the union and the firm collaborate on adoption of I 4.0? Some HPWS researchers advocate union-firm partnerships rather than more traditional types of industrial relations (Totterdill, 2017). Yet, in line with more critical HPWS research, our study reveals that partnerships could be problematic for union independence vis-à-vis HPWS. Unions and firms may have some overlapping interests on I 4.0, but it is unlikely that adoption will be less prone to labour-management conflicts than will HPWS. Thus, unions will also need to maintain a strong ‘monopoly face’ (Pohler and Luchak, 2015) to remain credible and independent in joint technology initiatives.

Finally, UNIFOR’s initial response to HPWS in the 1990s drew upon but, also, facilitated mass rank-and-file support in part via strong counter-narratives. Bosch and Schmitz-Kiebler’s (2020) study emphasizes the need to bring shop-floor employees more fully into I 4.0 decisions. In our study, worker health and safety was one key HPWS counter-narrative, and similar concerns over I 4.0 may, also, prove an important way for unions to develop I 4.0 counter-narratives while increasing internal union debate on this issue and participation in a policy of technology co-determination (Gaddi et al., 2017). As such, I 4.0 negotiation could in itself serve as one basis for union renewal.

Conclusions

In this paper, we have argued that UNIFOR union and employment relations have generally played a role in shaping the uneven adoption, if not hybridization, of HPWS. While I 4.0 adoption is still in its early stages, the union’s role in negotiating HPWS has important implications for I 4.0, including the form and nature of union-management relations in technology adoption, in the role of shop-floor representatives, and in overall national or industry-wide union strategies. If I 4.0 is a path-altering transition for employment relations, then union experiences with HPWS may provide a relevant guide to their I 4.0 strategies.

Parties annexes

Notes

-

[1]

Previously, it was the UAW Canada until 1985 and the CAW until 2013. It then merged with the Communications, Energy and Paper Workers Union (CEP) to form UNIFOR in 2013.

-

[2]

In response to the 2008-2009 crisis, unionized assemblers demanded that new hires be employed permanently with lower wages and benefits. Unlike the UAW, UNIFOR has a 10-year ‘grow in’ period during which new employees can reach full wages and benefits.

Parties annexes

Acknowledgment

We gratefully acknowledge the Automotive Policy Research Centre (APRC) at McMaster University and the Social Sciences and Humanities Research Council (SSHRC-430-2017-00442) for funding this project. We also wish to thank the helpful comments of two anonymous reviewers and the special issue editors. Finally, we thank Carlo Sica for his skillful interview transcribing.

References

- Aghazedeh, Seyed-Mahmoud and Mojtaba Seyedin (2004) “The High Performance Work System: Is it Worth Using?” Team Performance Management, 10 (3/4), 60-64.

- Appelbaum, Eileen (2002) “The Impact of New Forms of Work Organizations on Workers.” In Gregor Murray, Jacques Belanger, Anthony Giles and Paul-Andrew Lapointe (eds.) Work and Employment Relations in the High Performance Workplace. London: Continuum, p. 120-149.

- Avogara, Matteo (2018) “Evolution of Trade Unions in Industry 4.0: A German and Italian Debate.” In Edoardo Ales, Ylenia Curzi, Tommaso Fabbri, Olga Rymkevich, Iacopo Senatori and Giovanni Solinas (eds.), Working in Digital and Smart Organizations: Legal Economic and Organizational Perspectives on the Digitalization of Labour Relations. London: Palgrave Macmillan, p. 165-190.

- Bacon, Nicholas and Paul Blyton (2006) “The Effects of Co-Operating or Conflicting Over Work Restructuring: Evidence from Employees.” Sociological Review, 54 (1), 1-19.

- Bosch, Gerhard and Jutta Schmitz-Kießler (2020) “Shaping Industry 4.0 – An Experimental Approach Developed by German Trade Unions.” Transfer: European Review of Labour and Research, DOI: 10.1177/1024258920918480, 1-18.

- Charles River Associates (2001) Competitiveness Factors for Attracting and MaintainingAutomotive Investment: Comparison Between Canada and Mexico. Report prepared for Industry Canada and the Ontario Ministry of Economic Development and Trade, Retrieved from http://publications.gc.ca/Collection/C2-609-2002E.pdf (February 12th 2017).

- Danford, Andy, Mike Richardson, Paul Stewart, Stephanie Tailby and Martin Upchurch (2008) “Partnership, High Performance Work Systems and Quality of Work Life.” New Technology, Work and Employment, 23 (3), 151-166.

- Frost, Anne (2000) “Explaining Variation in Workplace Restructuring: The Role of Local Union Capabilities.” Industrial Relations Review, 53 (4), 559-578.

- Gaddi, Matteo, Nadia Garbellini and Francesco Garibaldo (2018) Industry 4.0 and its Consequences for Work and Labour: Field Research Report on the Implementation of Industry 4.0 in a Sample of Italian Companies. Retrieved from: Fondazione Sabatini Bologna, Italy. https://www.fondazionesabattini.it/ (June 15th 2018).

- Gibbs, Samuel (2016) “Mercedes-Benz Swaps Robots for People on its Assembly Lines.” The Guardian, 26 February. Retrieved from: https://www.theguardian.com/technology/2016/feb/26/mercedes-benz-robots-people-assembly-lines (February, 26th 2016).

- Gindin, Sam (1995) The Canadian Auto Workers: The Birth and Transformation of a Union. Toronto: Lorimer.

- Grimshaw, Damien and Jill Rubery (2005) “Inter-Capital Relations and the Network Organisation: Redefining the Work and Employment Nexus.” Cambridge Journal of Economics, 29, 1027-1051.

- Groshen, Erica, Susan Helper, John Paul MacDuffie and Charles Carson (2018) Preparing US Workers and Employers for an Autonomous Vehicle Future, Report Prepared for Securing America’s Future Energy. Retrieved from: https://avworkforce.secureenergy.org/wp-content/uploads/2018/06/Groshen-et-al-Report-June-2018-1.pdf (10-17-18).

- Helper, Susan, Raphael Martins and Robert Seamans (2017) Value Migration and Industry 4.0: Theory, Field Evidence, and Propositions. Presented at the Torino RENIR Workshop, 19-20th February 2018.

- Holmes, John and Pradeep Kumar (1998) “Chrysler Canada’s Windsor Assembly Plant: Lean Production through Bargained incremental change.” In Huberto Nunez and Steve Babson (eds.), Confronting Change Auto Labor and Lean Production. Benemerita Universidad Autonoma di Pueblo, p. 257-279.

- Knight, Thomas and David McPhillips (1989) “Technological Change and Collective Bargaining in Canada.”. Emploee Relations, 11 (4), 17-20.

- Kochan, Thomas, Wilma Liebman and Inez von Weitershausen (2018) “Codetermining the Future of Work: Lessons from Germany.” Retrieved from: https://iwer.mit.edu/2018/10/09/codetermining-the-future-of-work-lessons-from-germany/ (12-05-18).

- Kopp, Ralf, Jurgen Howaldt and Jurgen Schultze (2016) “Why Industry 4.0 Needs Workplace Innovation: A Critical Look at the German Debate on Advanced Manufacturing.” European Journal of Workplace Innovation, 2 (1), 7-23.

- Kristensen, Peer and Robson Rocha (2012) “New Roles for the Trade Unions: Five Lines of Action for Carving out a New Governance Regime.” Politics and Society, 40 (3), 453-479.

- Krzywdzinski, Martin (2017) “Accounting for Cross-Country Differences in Employee Involvement Practices: Comparative Case Studies in Germany, Brazil and China.” British Journal of Industrial Relations, 55 (2), 321-346.

- Krzywdzinski, Martin, Urlich Jurgens and Suzanne Pfeiffer (2016) The Fourth Revolution: The Transformation of Manufacturing Working the Age of Digitalization. WZB, Report.

- Lewchuck, Wayne, Paul Stewart and Charlotte Yates (2001) “Quality of Working Life in the Automobile Industry: A Canada–UK Comparative Study.” New Technology Work and Employment, 16, 72-87.

- Lévesque, Christian and Gregor Murray (2010) “Understanding Union Power: Resources and Capabilities for Renewing Union Capacity.” Transfer: European Review of Labour and Research, 16 (3), 333-350.

- Lippert, Inge, Tony Huzzard, Ulrich Jurgens and William Lazonick (2014) Corporate Governance, Employee Voice and Work Organization: Sustaining High-Road Jobs in the Automotive Supply Industry. Oxford: Oxford University Press.

- Livingston, David and Milosh Raykov (2008) “Workers Power and Intentional Learning amongst Non-Managerial Employees: 2004 A 2004 Benchmark Survey.” Relations industrielles/Industrial Relations, 63 (1), 30-56.

- Liu, Wenchaun, James Guthrie, Patrick Flood and Sarah MacCurtain (2009) “Unions and the Adoption of High Performance Work Systems: Does Employment Security Play a Role?” Industrial and Labor Relations Review, 63 (1), 109-127.

- Lloyd, Caroline and Jonathan Payne (2019) “Rethinking Country Effects: Robotics, AI and Work Futures in Norway and the UK.” New Technology, Work and Employment, 34 (3), 208-225.

- Moody, Kim (2018) “High Tech, Low Growth: Robots and the Future of Work.” Historical Materialism, 26 (4), 3-34.

- Mordue, Greig and Brendan Sweeney (2017) “The Commoditisation of Automotive Assembly: Canada as a Cautionary Tale.” International Journal of Automotive Technology and Management, 17 (2), 169-189.

- Osterman, Paul (2018) “In Search of the High Road: Meaning and Evidence.” ILR Review, 71 (1), 3-34.

- Pohler, Dianne and Andrew Luchak (2015) “Are Unions Good or Bad for Organizations? The Moderating Role of Management’s Response.” British Journal of Industrial Relations, 53 (3), 423-459.

- Rainnie Al, Mark Dean (2020) “Industry 4.0 and the Future of Quality Work in the Global Digital Economy.” Labour and Industry: A Journal of the Social and Economic Relations of Work, 30 (1), 16-33.

- Rinehart, Jim, Huxley Chris and Robertson David (1997) Just another Car Factory? Lean Production and his Discontents. Ithaca: IRR Press.

- Siemiatycki, Elliot (2012) “Forced to Concede: Permanent Restructuring and Labour’s Place in the North American Auto Industry.” Antipode, 44 (2), 453-473.

- Sweeney, Brendan and Greig Mordue (2017) “The Restructuring of Canada’s Automotive Industry, 2005-2014.” Canadian Public Policy, 43 (1), 1-15.

- Tanguay, Real (2018) Drive to Win: Automotive Advisor Report. Canadian Automotive Partnership Council. Retrieved from: http://capcinfo.ca/images/PDF/CAPC_Automotive%20Report-en.pdf (September 18th, 2018).

- Totterdill, Peter (2017) “The Corporate Response to Industry 4.0.” European Journal of Workplace Innovation, 3 (2), 117-138.

- UNIFOR (2018) The Future of Work Is Ours: Confronting Risks and Seizing Opportunities of Technological Change. UNIFOR Toronto Ontario. Retrieved from: https://www.unifor.org/en/future-work-ours-confronting-risks-and-seizing-opportunities-technological-change-report (March 7th, 2019).

- United Auto Workers (2019) Proposed Resolution Special Convention on Collective Bargaining. 11-13 March, Detroit Michigan. Retrieved from: https://uaw.org/app/uploads/2019/02/Final-resolution-Book.pdf (June 21st, 2019).

- Waddington, John (2015) “Workplace Representation, its Impact on Trade Union Members and its Capacity to Compete with Management in the European Workplace” Transfer: European Review of Labour and Research, 20 (4), 537-558.

- Walworth, Scott (2010) “What Do Unions do to Innovation? An Empirical Examination of the Canadian Private Sector.” Relations industrielles/Industrial Relations, 65 (4), 543-561.

- Wells, Don (1993) “Are Strong Unions Compatible with the New Model of Human Resource Management?” Relations industrielles/Industrial Relations, 48 (1) 56-85.

- Wenten, Frido (2017) “Does it Matter what Workers Do? The Role of Workers’ Relational Agency in the Hybridization of TNC Subsidiaries in China and Mexico.” International Journal of Automotive Technology and Management, 17 (2), 190-204.

- Womack, James, Daniel Jones and Daniel Roos (1990) The Machine that Changed the World: The Story of Lean Production. New York: Free Press.

- Yates, Charlotte and John Holmes (2019) The Future of the Canadian Auto Industry. Ottawa: Canadian Centre for Policy Alternatives.

- Yin, Robert (2003) Case Study Research: Design and Methods. Thousand Oaks, CA: Sage.

Liste des figures

Figure 1

Union and HPWS Workplace Integration of Industry 4.0

Liste des tableaux

Table 1

Surveyed Plant Characteristics and Union HPWS Bargaining

10.7202/045585ar

10.7202/045585ar